Description

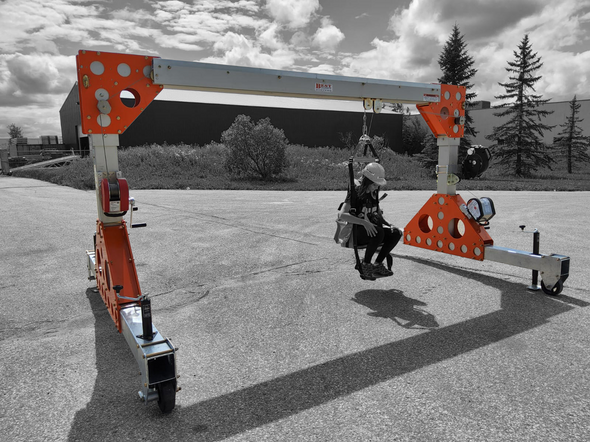

The Tuff Built 71011 A-Frame with Work Positioning Assembly is designed to offer safe and secure access to elevated or confined spaces while allowing workers to maintain freedom of movement during rescue maintenance or inspection operations. This A-frame system features a work positioning assembly that supports both rescue and work positioning tasks giving personnel a reliable way to hoist or lower workers while keeping them securely tethered to an anchor system.

Key Features:

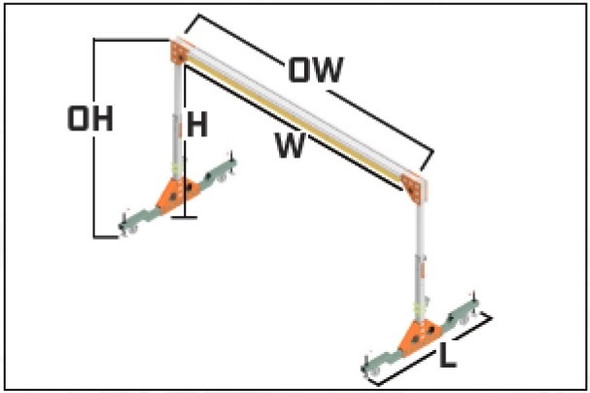

A-Frame Design:

The A-frame structure features two angled legs that support a horizontal crossbeam offering a stable and secure lifting platform for personnel and equipment.

This A-frame design is known for its greater stability compared to other lifting systems making it ideal for rescue operations and confined space entry scenarios.

Work Positioning Assembly:

The system includes a work positioning assembly allowing workers to safely maintain working positions while being elevated or lowered into confined or high-risk areas.

The work positioning system may include harnesses lanyards or ropes helping workers remain securely attached to the system while performing tasks at height or in confined spaces.

This ensures that workers can safely perform tasks or manipulate equipment while minimizing the risk of falling or being displaced during operations.

10L (Length) x 10H (Height):

10L (Length) and 10H (Height) refer to the dimensions of the A-frame. The length is 10 inches which likely refers to the spread of the A-frame (the horizontal distance between the legs or support base) providing a compact yet stable design for portable use.

The height of 10 inches indicates the vertical clearance provided by the A-frame which allows personnel to be safely elevated or lowered in a controlled manner during rescue or maintenance operations.

2R (2 Rescue):

2R indicates that the A-frame is designed for rescue operations and is capable of supporting the safe retrieval of two individuals or multiple people. This is ideal for multi-person rescue scenarios where workers may need to be lifted or lowered together in emergency situations.

2A (2 Anchor Points):

2A means the system includes two anchor points which are crucial for attaching lifelines ropes or winches. Having two anchor points increases the redundancy of the system enhancing safety during operations by providing multiple secure attachment points.

This feature is particularly important when working in high-risk environments where multiple safety connections are necessary.

RM (Rescue Model):

RM stands for Rescue Model meaning the system is designed specifically for emergency rescue and safe lowering/hoisting of personnel in hazardous environments.

Heavy-Duty Construction:

The Tuff Built 71011 A-frame is built using high-strength materials such as steel or aluminum ensuring that it is durable enough to withstand the stresses associated with lifting lowering and rescuing personnel or heavy equipment.

The frame is also designed to be corrosion-resistant making it ideal for use in outdoor environments or industrial settings where exposure to harsh conditions is common.

Portable and Easy Setup:

The system is designed for easy transportation and quick deployment allowing it to be rapidly set up in emergency situations or industrial job sites where access to elevated spaces is required.

Its lightweight construction ensures that it can be moved and assembled with minimal effort.

Common Uses:

Confined Space Rescue:

The Tuff Built 71011 A-frame is perfect for confined space rescue such as rescuing individuals from spaces like manholes silos tanks or pits. The work positioning assembly allows rescuers to safely enter retrieve or assist workers in tight spaces while maintaining secure attachment to the system.

Fall Protection and Work Positioning:

This A-frame system is ideal for use in construction sites industrial settings or during maintenance where workers are exposed to fall hazards or need to be positioned in elevated areas to perform tasks.

The work positioning assembly keeps workers securely attached while allowing them to perform hands-free tasks at height or in confined areas reducing the risk of accidents.

Industrial Maintenance and Inspections:

In industrial environments the system can be used for routine maintenance or inspections of elevated or hard-to-reach areas such as towers chimneys elevated platforms or roofs.

The A-frame with work positioning ensures that workers can safely reach and perform their tasks in high places without being at risk of falling.

Rescue Operations:

The Tuff Built 71011 A-frame is designed to be used by first responders or rescue teams during emergency situations to safely retrieve workers or victims from dangerous or difficult-to-access locations.

Specifications:

Dimensions:

Length: 10 inches (likely referring to the base spread or footprint of the frame ensuring stability)

Height: 10 inches (providing sufficient vertical clearance for lifting and lowering operations)

Material:

Steel or Aluminum construction for strength durability and corrosion resistance.

Anchor Points:

Includes two anchor points allowing for multiple secure attachment points for lifelines winches or ropes which is essential for maintaining safety during rescue operations.

Weight Capacity:

This system is designed to safely support significant weight generally several hundred pounds depending on the frame's configuration. This makes it suitable for lifting and lowering personnel or heavy equipment.

Safety Considerations:

Regular Inspections:

The A-frame should be inspected regularly to ensure it is in optimal working condition. This includes checking for any signs of wear corrosion or damage to the structure and the anchor points.

Proper Setup:

Ensure the A-frame is set up on level stable ground to maintain its integrity during lifting or lowering operations. The system should be securely anchored to prevent tipping or movement.

Training:

Personnel using this system should be trained in safe operation practices including securing lifelines attaching work positioning gear and performing rescue operations.