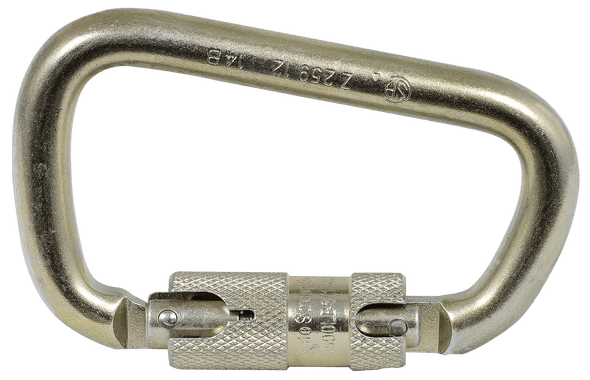

Carabiners and Hooks

What Are Carabiners and Hooks: Essential Safety Equipment Guide

Carabiners and hooks are spring-loaded metal connectors that secure workers to lifelines, anchor points, and safety equipment. These devices feature gate mechanisms like snap hooks, screw gates, and auto-locking systems that prevent accidental disconnection. All Safety provides certified carabiners and hooks meeting ANSI Z359.12 standards for fall protection applications. Common types include D-shaped carabiners for maximum strength, oval carabiners for smooth rope movement, and specialty hooks.

How Carabiners and Safety Hooks Work

Safety connectors work by using spring-loaded gates that open under pressure and automatically close when released. The gate mechanism creates a secure closure that typically withstands forces between 22kN to 50kN depending on the connector type. Auto-locking carabiners require two separate actions to open, preventing accidental release during use. Triple-action gates need twisting, lifting, and pulling motions simultaneously, while magnetic gates use powerful magnets to maintain closure.

Gate Mechanisms and Operation

Different gate types serve specific safety needs in various work environments. Screw gates offer maximum security for permanent connections but require more time to operate. Snap hooks provide quick attachment for frequent connections but offer less security than locking mechanisms. Twist-lock carabiners balance security with operational speed, making them ideal for rescue operations and technical rope work.

Key Benefits of Using Safety Carabiners and Hooks

The primary benefits include reliable fall protection connections, quick equipment attachment, and compliance with safety regulations. These connectors enable workers to maintain secure connections while allowing freedom of movement during tasks. Safety hooks reduce setup time compared to permanent attachment methods, increasing productivity while maintaining protection. Quality carabiners prevent equipment loss through secure tool tethering systems.

Operational Advantages

Modern safety connectors offer enhanced visibility through bright colors and reflective markings, improving safety in low-light conditions. Swivel mechanisms prevent line twist and equipment tangling during use. All Safety stocks connectors with visual load indicators that show when a device has experienced excessive force and needs replacement.

Important Limitations and Safety Considerations

Carabiners and hooks have significant limitations that users must understand. These devices cannot exceed their rated load capacity, typically ranging from 22kN to 50kN for major axis loading. Side loading dramatically reduces strength, often by 60-70% of rated capacity. Gate-open conditions reduce strength by approximately 30-50%, making proper closure critical for safety.

Environmental and Usage Restrictions

Extreme temperatures affect connector performance, with some materials becoming brittle below -40°C or losing strength above 60°C. Chemical exposure from acids, alkalis, or solvents can cause material degradation over time. Regular inspection is mandatory, as fatigue from repeated loading cycles eventually requires replacement regardless of visible condition.

Who Should Use Safety Carabiners and Hooks

Construction workers, utility technicians, wind energy specialists, and rope access professionals rely on these connectors for fall protection. Industrial maintenance teams use them for equipment positioning and material handling. Rescue personnel depend on specialized connectors for confined space operations and emergency response. Fall protection inspection services help ensure proper connector selection and maintenance.

Industry-Specific User Groups

Telecommunications workers need lightweight connectors for extended wear comfort during tower work. Oil and gas personnel require spark-resistant materials for hazardous environments. Marine workers benefit from corrosion-resistant stainless steel options for saltwater exposure. Manufacturing employees use high-frequency connectors designed for repeated daily operations.

When to Use Different Types of Connectors

Use auto-locking carabiners when connections will remain in place for extended periods or during rescue operations. Choose snap hooks for frequent connections and disconnections during routine work tasks. Screw gate carabiners work best for permanent anchor point connections or when maximum security is required. Select specialty hooks for specific equipment like fall protection systems and material handling applications.

Application-Specific Timing

Emergency situations require quick-release mechanisms that operate under load, while routine maintenance allows time for more secure locking systems. Overhead work benefits from connectors with captive eye features that prevent equipment loss. All Safety recommends using swivel connectors when rope or cable movement is expected during operations.

Cost Considerations for Safety Connectors

Basic snap hooks typically cost between $8-25 each, while premium auto-locking carabiners range from $35-85 depending on features and materials. Stainless steel connectors cost 40-60% more than aluminum versions but offer superior corrosion resistance. Specialty connectors with unique features like RFID tracking or load indicators can cost $100-200 each.

Total Cost of Ownership

Factor in inspection costs, replacement schedules, and training requirements when calculating connector expenses. Quality connectors typically last 5-10 years with proper maintenance, while budget options may require replacement every 2-3 years. Volume purchasing often provides 15-30% cost savings for standardized equipment programs.

Essential Tools and Accessories for Connector Use

Proper connector use requires inspection tools like magnifying glasses for crack detection and torque wrenches for proper gate adjustment. Cleaning supplies including wire brushes and approved solvents maintain connector function. Marking systems help track inspection dates and usage history. Storage solutions protect connectors from damage during transport and storage.

Maintenance Equipment Requirements

Digital calipers measure gate opening and component wear accurately. Load testing equipment verifies continued strength compliance. Documentation systems track connector service history and inspection results. All Safety provides guidance on proper maintenance tool selection for different connector types.

Alternatives to Traditional Carabiners and Hooks

Permanent attachment points eliminate the need for removable connectors in some applications but reduce flexibility. Integrated lanyard systems combine connectors with energy absorbers for simplified fall protection. Magnetic connectors offer hands-free operation but have limited load capacity. Quick-connect systems provide faster attachment than traditional carabiners but may have higher initial costs.

Emerging Connection Technologies

Smart connectors with digital monitoring capabilities track usage and alert users to maintenance needs. Lightweight composite materials reduce worker fatigue while maintaining strength requirements. Ergonomic designs improve ease of operation for workers wearing gloves or in awkward positions.

Common Mistakes and How to Avoid Them

Cross-loading occurs when force is applied perpendicular to the connector's major axis, dramatically reducing strength. Gate-open conditions happen when debris prevents proper closure or when users fail to verify locking. Incompatible equipment connections create stress concentrations that can cause failure. Using damaged connectors beyond their service life compromises safety.

Prevention Strategies

Regular training emphasizes proper connection techniques and inspection procedures. Visual inspection checklists help identify wear patterns and damage signs. Proper storage prevents accidental damage and contamination. All Safety offers training programs covering connector selection, use, and maintenance best practices.

Professional Selection and Buying Guide

Choose connectors based on required strength ratings, environmental conditions, and frequency of use. Verify certification markings and compliance with applicable safety standards like ANSI Z359.12 or EN 362. Consider gate type based on security requirements and operational needs. Evaluate material options including aluminum for lightweight applications and stainless steel for corrosive environments.

Quality Assessment Criteria

Look for clear strength markings, manufacturing date codes, and certification symbols. Check gate operation for smooth function and positive closure. Examine surface finish for signs of quality manufacturing. Review manufacturer warranties and technical support availability for long-term value.

Quick Selection Checklist for Industrial Carabiners and Hooks

- Verify strength ratings meet or exceed required safety standards (minimum 22kN major axis)

- Confirm gate mechanism matches security and operational requirements

- Check material compatibility with environmental conditions and chemical exposure

- Ensure size and shape accommodate all connecting equipment properly

- Review certification markings and compliance documentation thoroughly

- Calculate total quantity including spares and scheduled replacements

- Establish inspection schedules based on usage frequency and conditions

- Plan training programs for proper selection, use, and maintenance procedures

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

1" Carabiner | CSA CE | PeakWorks

Peakworks

$34.90Description Peakworks® Carabiners are perfect for mountaineering rock climbing fire & rescue protection construction caving & many other industrial occupations. This 1" carabiner is lightweight easy to use with a convenient double locking...$34.90 -

3/4" Carabiner | CSA | PeakWorks

Peakworks

$35.35Description Peakworks® Carabiners are perfect for mountaineering rock climbing fire & rescue protection construction caving & many other industrial occupations. This 1" carabiner is lightweight easy to use with a convenient double locking...$35.35 -

Carabiner 2" (51 mm) CSA for Scaffolding | Peakworks

Peakworks

$74.16Description Peakworks® Carabiners are perfect for mountaineering rock climbing fire & rescue protection construction caving & many other industrial occupations. This 1" carabiner is lightweight easy to use with a convenient double locking...$74.16