Lockout Stations

What Are Lockout Stations: Essential Safety Equipment Guide

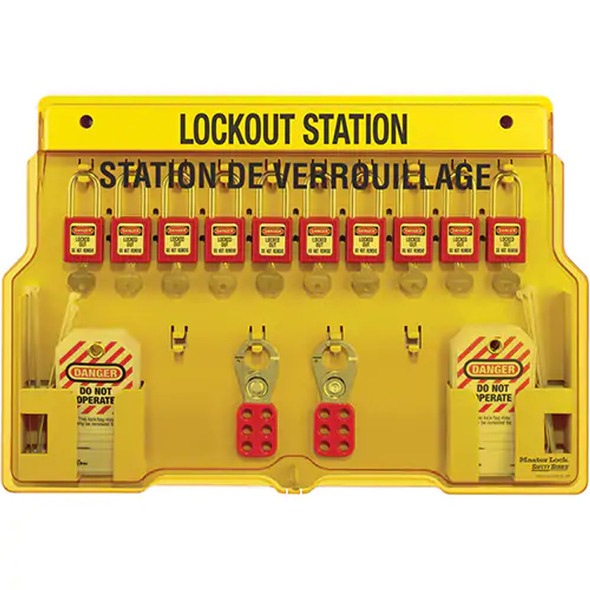

Lockout stations serve as centralized storage and organization points for lockout/tagout equipment in workplace safety programs. These wall-mounted or portable units safely store padlocks, tags, and other lockout devices used to prevent unauthorized equipment operation during maintenance or repairs. A lockout station ensures all necessary safety tools remain readily accessible and organized in one location, enabling quick response during maintenance procedures while keeping safety equipment protected from damage or loss. Modern lockout stations feature clear covers, labeled compartments, and various mounting options to suit different workplace environments.

Key Takeaways About Lockout Stations for Workplace Safety

- Lockout stations provide centralized storage for essential safety lockout equipment and devices.

- Safety teams use lockout stations to maintain organization and quick access during maintenance procedures.

- Each lockout station must meet specific OSHA requirements for proper lockout tagout program implementation.

- Regular inspection of lockout stations ensures all components remain in proper working condition.

- Different industries require varying sizes and types of lockout stations based on equipment needs.

- Proper placement of lockout stations improves emergency response time and worker compliance.

- Documentation stored within lockout stations helps maintain safety procedure compliance.

Common Applications and Essential Uses for Lockout Equipment

Lockout stations protect workers across various industrial settings by providing organized access to lockout accessories that prevent equipment accidents. Manufacturing facilities use these stations near machinery control points, while maintenance teams position portable units for mobile operations. The stations also store safety tags that communicate important equipment status and warnings.

Critical Zones for Lockout Station Placement

Strategic placement of lockout stations maximizes their effectiveness. Common locations include mechanical rooms, electrical control centers, and maintenance workshops. Some facilities incorporate stations into larger safety information centers for comprehensive protection.

How to Choose the Right Lockout Station: Complete Selection Guide

When selecting a lockout station, consider the number of padlock positions needed, construction material durability, and cover type. Look for stations with clear organization systems, proper labeling, and secure mounting options. The best lockout stations include space for procedure documentation and safety signs that reinforce proper protocols.

Essential Features of Lockout Stations Explained in Detail

Quality lockout stations incorporate several key features. Durable materials resist workplace conditions, while clear covers allow quick visual inspection of contents. Many stations include specialized hooks for lockout tags that track equipment status and dedicated spaces for procedure cards.

Industry Applications and Professional Standards

Manufacturing plants, energy facilities, and maintenance operations rely on properly equipped lockout stations. Each industry requires specific configurations based on equipment types and maintenance procedures. Processing plants often combine lockout stations with hazard warning placards for complete safety coverage.

Industry-Specific Applications

- Manufacturing Facilities: Handle complex machinery requiring multiple lockout points. These operations need large-capacity stations with group lockout capabilities and documentation storage for detailed procedures.

- Power Generation Plants: Deal with high-voltage equipment and multiple energy sources. Their stations require extra capacity for specialized electrical lockout devices and voltage testing equipment storage.

- Chemical Processing Plants: Focus on valve lockouts and pipeline maintenance. These facilities need corrosion-resistant stations with space for chemical-specific lockout devices.

- Automotive Service Centers: Manage vehicle maintenance and repair operations. Their stations typically include compact, mobile units with specific holders for common automotive lockout tools.

- Construction Sites: Require portable lockout solutions. These operations benefit from weather-resistant stations that can be easily relocated as work areas change.

- Food Processing Plants: Need sanitary lockout solutions. These facilities use stainless steel stations that maintain cleanliness standards while protecting essential safety equipment.

Safety Lock Box Daily Operations and Practical Tips

Daily lockout station management requires consistent procedures and regular checks. Users must sign out equipment, document usage, and return items promptly. Many facilities integrate lockout stations with safety inspection equipment storage for comprehensive protection.

Effective Station Management Practices

Successful lockout programs include regular audits of station contents, verification of lock assignments, and updates to procedure documentation. This systematic approach ensures equipment remains ready for immediate use during maintenance operations.

Padlock Center Care and Maintenance Requirements

Regular maintenance keeps lockout stations functional and compliant. Clean stations monthly, inspect locks quarterly, and verify all components function properly. Combine maintenance checks with reviews of safety information center updates to maintain current procedures.

Group Lock Holder Compliance and Regulations

Lockout stations must meet OSHA standard 1910.147 requirements for control of hazardous energy. Regular audits ensure compliance with these standards and identify needed updates. Many facilities incorporate specialized lockout stations for specific equipment types.

Safety Lockout Cabinet Problems and Solutions

Common issues include overcrowded stations, missing documentation, and damaged components. Address these problems through regular inventory checks, proper sizing, and prompt replacement of damaged items. Consider integrating stations with comprehensive safety signage systems for better visibility.

Lockout Equipment Investment Planning Guide

Investment in quality lockout stations provides long-term safety benefits. Consider initial costs, expansion capabilities, and maintenance requirements when selecting stations. Many organizations combine station purchases with complete lockout accessory packages for cost efficiency.

Quick Selection Checklist for Lockout Stations

- Verify compliance with current OSHA lockout/tagout requirements and standards

- Confirm station capacity matches workplace lockout device quantity needs

- Check mounting location accessibility and visibility for all workers

- Ensure station material compatibility with workplace environmental conditions

- Calculate total program costs including locks, tags, and documentation

- Review manufacturer warranty and replacement part availability

- Schedule regular maintenance checks and component replacement intervals

- Plan for future expansion and additional lockout equipment needs

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

Trilingual Covered Lock Station - 4 Padlock Capacity, Padlocks Not Included

Master Lock

$162.32Description Station message printed in English. Spanish and French labels included for optional application Resilient polycarbonate material provides ultimate heat resistance and impact strength superior to typical stations Translucent lockable...$162.32 -

Compact Lockout Station, 4 Padlock Capacity - Padlocks Included | Master Lock

Master Lock

$166.21Description Compact lockout center locates machine specific lockout devices and padlocks near lockout point Hanger clips hold padlocks and/or hasps Valve lockouts, plug lockouts, tags and much more Contains: Two SAO595 and two SAO594 breaker...$166.21 -

Lockout Station, Aluminum Padlocks, 4-Padlock Capacity | Master Lock

Master Lock

$317.84Description Compliant with OSHA "One employee, One lock, One key" directive Zenex ™ locks available with up to 100,000 key changes available to fit even the largest lockout systems Integrated, one-piece molded construction eliminates...$317.84 -

Lockout Station, 4 Padlock Capacity (Padlocks Included) | Master Lock

Master Lock

$327.56Description Exclusive translucent lockable cover protects contents and prevents loss of valuable safety lockout padlocks Integrated, one-piece molded construction eliminates loose parts 12 Safety Series ™ heavy-duty bilingual "Do Not Operate"...$327.56 -

Lockout Station, Aluminum Padlocks, 10-Padlock Capacity | Master Lock

Master Lock

$603.61Description Lockout stations are bilingual with English/ French labels and lockout tags Exclusive translucent lockable cover protects contents and prevents loss of valuable safety lockout padlocks 12 Safety Series ™ heavy-duty bilingual "Do...$603.61 -

Lockout Stations, 10 Padlock Capacity W/ Padlocks | Master Lock

Master Lock

$617.22Description Integrated, one-piece molded construction eliminates loose parts Resilient polycarbonate material provides twice the heat resistance and quadruples the impact strength of typical stations Reinforced snap-lock clips provide easy...$617.22 -

Electrical Focus Lockout Stations W/ Thermoplastic Padlocks, 16 Padlock Capacity

Master Lock

$724.14Description Durable construction to ensure long life in manufacturing facilities Eight hanger clips hold two padlocks or lockout hasps each Includes: 6 padlocks, 1 hasp, 1 snap-on hasp, 1 compact plug prong lockout, 1 plug cover, 4 circuit breaker...$724.14 -

Lockout Station, Aluminum Padlocks, 20 Padlock Capacity | Master Lock

Master Lock

$1,147.93Description Lockout stations are bilingual with English/ French labels and lockout tags Resilient polycarbonate material provides twice the heat resistance and quadruples the impact strength of typical stations Integrated, one-piece molded...$1,147.93