Respiratory Accessories

Understanding the Basics: What Are Respiratory Accessories?

Respiratory accessories encompass the supplementary products designed to maintain, clean, and extend the life of respiratory protection equipment. These essential components include cleaning wipes, sanitizers, storage cases, filters, cartridge covers, and maintenance kits specifically engineered for respirators and breathing apparatus. Respiratory accessories serve to ensure proper functionality, hygiene, and compliance with safety regulations for all types of respiratory protection. These products are crucial for workers in industries with airborne hazards such as construction, manufacturing, healthcare, and chemical processing, where maintaining respiratory equipment in optimal condition directly impacts user safety and health outcomes.

Key Takeaways About Respiratory Accessories

- Respiratory accessories extend the life and functionality of respirator equipment through proper maintenance and cleaning.

- Regular sanitization with appropriate respiratory accessories prevents cross-contamination and reduces infection risks.

- Compatible accessories ensure respirators maintain their protective seal and filtration efficiency.

- Workplace safety regulations often require documented maintenance of respiratory equipment using approved accessories.

- Quality respiratory accessories help companies maintain compliance with OSHA, NIOSH, and CSA respiratory protection standards.

- Convenience features in respiratory accessories increase the likelihood of consistent respirator maintenance by workers.

- Proper storage accessories protect respirators from environmental damage when not in use.

Common Applications and Use Cases for Protection Equipment Maintenance

Respiratory accessories find extensive use across numerous workplace scenarios where maintaining clean, functional respiratory equipment is essential. Construction workers utilize respirator wipes to clean dust and debris after working in particulate-heavy environments. Healthcare professionals depend on specialized sanitizing products to prevent pathogen transmission between shifts. Manufacturing facilities implement comprehensive maintenance programs with testing kits to verify respirator integrity. Mining operations rely on specialized storage cases to protect equipment from harsh environmental conditions. Oil and gas workers use cleaning accessories formulated to remove stubborn hydrocarbon residues. Agriculture workers benefit from maintenance kits designed to address pesticide and organic contaminant removal from half mask respirators that provide essential protection.

How to Choose the Right Respiratory Accessories for Equipment Care

Selecting appropriate respiratory accessories requires consideration of several critical factors. First, verify compatibility with your specific respirator model and brand, as proprietary connections and designs vary significantly. Assess the cleaning efficiency against the contaminants in your work environment, whether dust, oil, biological materials, or chemicals. Consider the frequency of use to determine quantity requirements and convenience features. Safety experts recommend choosing accessories that maintain compliance with applicable standards like NIOSH, OSHA, and CSA. Evaluate storage requirements, particularly in extreme temperatures or high-humidity environments where specialized cases might be necessary. Avoid common mistakes such as using general-purpose cleaners that may degrade respirator materials or compromise filtration efficiency over time.

Essential Respiratory Accessories Features Explained for Users

Understanding key features of respiratory accessories enhances selection and usage efficacy. Compatibility indicators ensure accessories work with specific respirator brands and models, preventing mismatched components. Material safety certifications confirm accessories won't cause skin irritation or introduce harmful chemicals during cleaning. Anti-fog treatments in certain accessories help maintain clear vision for full face respirators with comprehensive eye protection. Biodegradable formulations balance effective sanitization with environmental responsibility. Quick-drying properties minimize downtime between cleaning and reuse. Anti-static features prevent dust attraction after cleaning. Portable packaging options support field maintenance when fixed facilities aren't available. For different applications, prioritize quick-cleaning capabilities for emergency services, thorough sanitization for healthcare, and anti-corrosion properties for chemical industries.

Professional and Industry Usage of Protective Equipment Components

Professional environments implement structured approaches to respiratory accessory usage based on specific industry requirements. Industrial hygienists develop maintenance schedules that incorporate appropriate cleaning accessories based on exposure assessments. Emergency responders require quick-turnaround sanitization accessories that allow rapid redeployment of equipment. Healthcare facilities follow stringent infection control protocols with medical-grade sanitizing accessories. Manufacturing quality control departments conduct regular fit testing using specialized accessories to verify continued protection levels. Construction safety managers maintain respirator cleaning stations with appropriate wipes and solutions. Oil and gas operations implement accessory usage logs to ensure compliance with safety regulations. The mining industry requires specially formulated cleaning accessories capable of removing mineral particulates without damaging cartridges and filters that capture airborne contaminants.

Industry-Specific Applications

- Construction - Faces high levels of silica dust and requires respiratory accessories that can effectively remove particulates without damaging filter media while being rugged enough for jobsite conditions.

- Healthcare - Needs medical-grade sanitization accessories that eliminate pathogens completely while maintaining biocompatibility with sensitive environments and quick turnaround times between shifts.

- Manufacturing - Requires specialized cleaners that can remove oil-based contaminants and metal particulates while preserving respirator integrity through hundreds of cleaning cycles.

- Chemical Processing - Depends on chemical-resistant cleaning accessories that won't react with residual substances while ensuring complete decontamination of specialized respiratory equipment.

- Mining - Uses heavy-duty maintenance kits designed for removing embedded mineral dust while functioning in remote locations with limited facilities.

- Pharmaceuticals - Implements stringent cleaning protocols with accessories that leave no residue and maintain sterile conditions required for production environments.

Daily Use and Practical Aspects of Breathing Mask Supplies

The practical implementation of respiratory accessories in daily routines significantly impacts protection effectiveness. Workers should establish consistent end-of-shift cleaning procedures using appropriate wipes or solutions to prevent contaminant buildup. Portable cleaning accessories facilitate maintenance in field operations where fixed facilities aren't available. Storage cases protect respirators between uses, preventing damage from UV exposure, dust, and physical impacts. Convenience challenges include ensuring accessibility of cleaning supplies at point-of-use locations. Practical limitations arise when cleaning in extreme temperatures affects product efficacy. Organizations overcome these challenges by creating dedicated maintenance stations with respiratory accessories readily available for worker convenience. Individual-use packaging prevents cross-contamination in multi-user environments where respiratory equipment might be shared.

Standards and Quality Requirements for PPE Cleaning Products

Quality respiratory accessories adhere to stringent standards ensuring effectiveness and safety. NIOSH guidelines outline appropriate maintenance procedures and compatible accessory types for approved respirators. OSHA regulations require employers to provide suitable cleaning and disinfecting supplies as part of respiratory protection programs. Health Canada and CSA standards establish minimum performance requirements for respiratory equipment maintenance products. ISO certification indicates manufacturing consistency and quality management. Safety experts recommend selecting accessories explicitly approved by respirator manufacturers to maintain warranty coverage and performance guarantees. Quality indicators include detailed compatibility listings, clear usage instructions, and appropriate hazard warnings. Third-party testing verification demonstrates efficacy against specific contaminants. Appropriate shelf-life labeling ensures respiratory protection remains effective through proper maintenance.

Investment and Value Considerations for Mask Maintenance Items

The cost-benefit analysis of respiratory accessories extends beyond purchase price to long-term respiratory program value. Initial price variations reflect differences in formulation sophistication, packaging convenience, and quantity per unit. Premium accessories typically offer enhanced cleaning efficacy, longer shelf life, and broader compatibility across respirator types. Budget options may require more frequent application or provide less convenience features while still meeting basic requirements. Ongoing costs include regular replenishment based on usage frequency and workforce size. Bulk purchasing reduces per-unit costs for larger organizations, while smaller teams might benefit from subscription services ensuring timely replacement. The true value proposition incorporates reduced respirator replacement frequency, decreased downtime, and potential reduction in respiratory illness claims among workers using properly maintained equipment with disposable masks requiring different maintenance approaches than reusable options.

Quick Selection Checklist for Respiratory Accessories

- Verify compatibility with your specific respirator brand and model.

- Confirm sanitizing efficiency against workplace-specific contaminants.

- Measure storage space requirements for accessory kits and supplies.

- Check quantity per package against your team size needs.

- Calculate total cost including frequency of replacement requirements.

- Assess ease of use to ensure consistent worker compliance.

- Determine if specialized training is needed for proper application.

- Establish regular inventory checks to maintain adequate supplies.

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

Handpump For Neutral Desinf. Clean-CAN | Draeger

Draeger

$2.16This manual handpump accessory is designed for convenient dispensing of Neutral Disinfectant Clean CAN, ensuring safe, controlled application for workplace sanitation protocols. The Handpump for Neutral Disinfection Clean-CAN from Draeger is a...$2.16 -

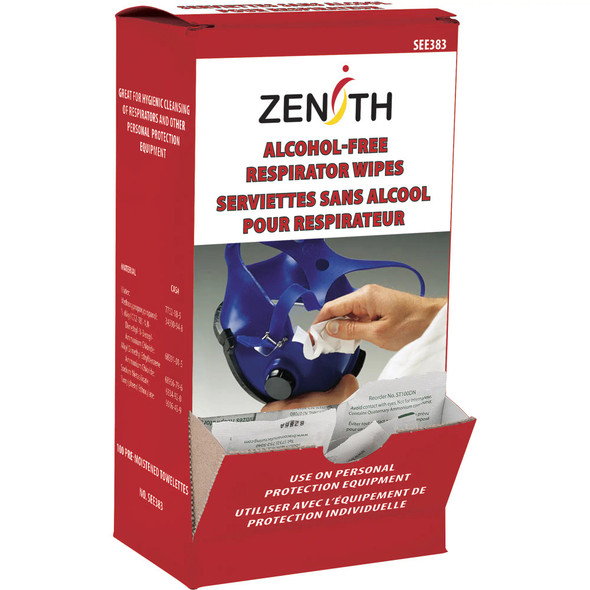

Respirators & PPE Cleaning Wipes | Zenith

Zenith

$15.28Description For rubber or latex face and mouth pieces, respirators, etc. Alcohol-free Avoids "drying-out" associated with alcohol based cleaners Individually packaged Specifications Format: Wipes Length: 8" ...$15.28 -

Bulb Aspirator SPPT | Draeger

Draeger

$36.57The Bulb Aspirator SPPT from Draeger is a replacement aspirator bulb designed for use with Draeger’s sampling and detection tubes. This device enables manual air sampling for gas detection kits in both field and laboratory testing environments. It...$36.57 -

Combination Filter Bayonet A1B1E1K1HgP3 R D | Draeger

Draeger

$37.28This is a combination gas + particle (aerosol) filter (i.e. it protects against both gases/vapors and particulates). It uses a bayonet connection (side-mount) compatible with Dräger masks with bayonet fittings (for example, X‑plore 3300, 3500...$37.28 -

Hood For Bitrex Fit Test Kit | Draeger

Draeger

$61.56Replacement hood for use with Bitrex fit test kits. Ensures hygiene and proper aerosol containment during respirator fit testing procedures. The Hood for Bitrex Fit Test Kit is a specialized accessory designed to enhance the fit testing process when...$61.56 -

Bitrex Sensitive Solution | Draeger

Draeger

$62.24Bitrex sensitive solution used in qualitative respirator fit testing. Detects mask leakage by taste; essential for initial fit test sensitivity assessment. Bitrex Sensitive Solution is a specialized product used primarily in industrial, laboratory, and...$62.24 -

Bitrex Fit Test Solution | Draeger

Draeger

$62.24Fit Test Solution (Bitrex) for use in qualitative fit testing of respirators. Reveals leakage by taste response; ensures mask seal integrity. The solution is used in conjunction with Draeger's Quantitative Fit Test Kits to evaluate the fit of respirators...$62.24 -

Fit Test Adapter | Draeger

Draeger

$139.54Fit Test Adapter for connecting Draeger respirators to fit test apparatus. Product Overview Model: 4055655 Compatibility: Specifically designed for the Dräger X-plore® 2100 half mask respirator. Purpose: Enables quantitative fit testing...$139.54 -

Flow-Check Ampoules (3 pcs.) | Draeger

Draeger

$143.64Flow-Check ampoules (3 pcs.), replacement fog ampoules for Flow Check air movement tester. The Flow-Check Ampoules (3 pcs.) by Draeger are specialized diagnostic tools used for testing the function and performance of Draeger gas detection equipment...$143.64 -

Mask Spectacles (P-NOVA) | Draeger

Draeger

$177.84Product Overview The P-NOVA Mask Spectacles are specifically engineered for compatibility with Dräger's respiratory protection products, such as full-face masks. The spectacles are designed to fit inside the mask's visor and allow wearers to...$177.84 -

FPS 7000 Mask Spectacles | Draeger

Draeger

$184.68The FPS 7000 Mask Spectacles by Dräger are high-quality protective eyewear designed for use with Dräger’s FPS 7000 full-face respiratory masks. These spectacles are specifically engineered to provide superior comfort, clarity, and...$184.68 -

Mini Rapid Adaptor | Draeger

Draeger

$198.36The Mini Rapid Adaptor from Draeger is a versatile and compact accessory designed to facilitate the quick and secure connection of breathing apparatus to air supply sources. This adaptor is especially useful in environments where rapid deployment of...$198.36 -

Irritant Smoke Fit Test Kit | Draeger

Draeger

$205.20This Irritant Smoke Fit Test Kit by Dräger delivers a fast and effective way to conduct qualitative fit tests on tight-fitting respirators. Safe, easy-to-use, and suitable for occupational safety programs and regulatory compliance. The Irritant...$205.20 -

Fit Test Adapter Kit X-plore 2100 | Draeger

Draeger

$255.82Adapter kit for X-plore 2100 half mask respirators. Enables fit testing according to industry standards; includes adapters and instructions for use. The FIT TEST ADAPTER KIT X-PLORE 2100 is designed to support the proper fit testing of respiratory...$255.82 -

Dual RAP P | Draeger

Draeger

$387.14Dual RAP P device for simultaneous connection of two air supply hoses to one mask or system. Enhances flexibility for maintenance and rescue teams. The Draeger Dual RAP P is a state-of-the-art, dual-purpose respiratory protection system, designed for use...$387.14 -

Fit Test Adapter (P & RA Masks) | Draeger

Draeger

$571.82Adapter for fit testing Dräger P and RA series masks. Enables compatibility with standard fit testing kits for regulatory compliance and effective mask seal verification. The Fit Test Adapter (P & RA Masks) is an accessory designed to facilitate...$571.82