Reflective Tapes

Understanding the Basics: What Are Reflective Tapes and Why They Matter

Reflective tapes consist of specialized materials designed to reflect light back to its source, significantly enhancing visibility in low-light conditions or darkness. These safety products contain microscopic glass beads or prismatic patterns embedded within flexible adhesive backing materials. Reflective tapes function by capturing incoming light from sources like headlights or flashlights and redirecting that light back toward the viewer, creating high visibility from considerable distances. These essential visibility tools serve critical functions across numerous industries including construction, transportation, warehousing, and emergency services. Anyone responsible for workplace safety, vehicle compliance, or nighttime visibility needs these versatile safety products.

Key Takeaways About Reflective Tapes for Enhanced Safety and Visibility

- Reflective tapes increase nighttime visibility by returning light directly to its source through specialized reflective materials.

- Different grades of reflective tape provide varying levels of brightness suitable for specific application requirements.

- Weather-resistant reflective tapes maintain performance in harsh outdoor conditions including rain, snow, and extreme temperatures.

- Colors and patterns on reflective tapes follow specific standards to communicate different safety messages across industries.

- Proper installation on clean, dry surfaces ensures optimal adhesion and longevity of reflective tape applications.

- Regulatory compliance often mandates specific reflective tape usage on vehicles, equipment, and facility markings.

- Regular inspection and maintenance of reflective tapes preserves visibility performance throughout their service life.

Common Applications and Use Cases for High-Visibility Safety Materials

Reflective tapes serve essential functions across numerous industries and applications. In transportation, these visibility enhancers mark commercial vehicles, trailers, and heavy equipment to meet DOT requirements for nighttime visibility. Within warehouses and industrial facilities, reflective tapes create clearly marked pedestrian pathways, highlight potential hazards, and identify emergency equipment locations. Construction sites utilize these safety products to mark temporary barriers, equipment, and hazardous zones. For personal safety, workers incorporate high-visibility clothing with reflective strips to maintain visibility during roadside work or low-light conditions. Even recreational applications benefit from reflective materials on bicycles, jogging gear, and outdoor equipment for nighttime safety.

How to Choose the Right Reflective Tapes: Selection Factors for Safety

Selecting appropriate reflective tape requires consideration of several critical factors. First, identify the required reflectivity grade—engineer grade for basic applications, high-intensity for improved visibility, or diamond grade for maximum brightness in critical safety situations. Consider environmental exposure conditions, as some tapes offer superior resistance to moisture, UV radiation, temperature fluctuations, and chemical exposure. Evaluate surface compatibility with your application material, whether metal, plastic, fabric, or concrete. Width and length requirements depend on specific application standards and visibility needs. Adhesive strength must match the intended surface and expected lifespan. Safety professionals recommend choosing products that meet relevant industry standards like ASTM D4956 or MUTCD specifications to ensure compliant traffic safety implementations.

Essential Reflective Tape Features Explained for Optimal Performance

Reflective coefficient determines brightness and visibility distance, with higher values providing greater nighttime detection. Durability factors include weather resistance, UV stability, and temperature tolerance, directly impacting service life in outdoor applications. Adhesive quality affects installation success and longevity, with options ranging from standard pressure-sensitive to specialized formulations for difficult surfaces. Color selection carries specific meanings—red/white patterns for vehicles, solid white for general visibility, and fluorescent colors for daytime attention. Some advanced reflective tapes incorporate additional features like photoluminescent properties for emergency situations when no light source is available. Pattern designs like chevrons or alternating colors enhance visual recognition and communicate specific hazard information according to established safety conventions.

Professional and Industry Usage: How Experts Implement Visual Safety Systems

Safety professionals deploy reflective tapes according to industry-specific requirements and best practices. Commercial fleet managers ensure vehicles maintain DOT-compliant conspicuity tape patterns to avoid citations and improve accident prevention. Industrial safety coordinators create comprehensive facility marking systems that integrate reflective elements with clear safety signage for maximum effectiveness. Construction safety officers implement temporary marking systems that highlight changing hazards throughout project phases. Emergency response vehicles utilize specialized highly reflective patterns that maximize visibility during critical situations. Manufacturing environments benefit from floor marking programs that incorporate reflective materials to maintain safe traffic patterns even during power outages or low-light conditions. Professional application techniques ensure proper surface preparation, temperature conditions, and installation methods that maximize adhesion and performance.

Industry-Specific Applications

- Construction companies face visibility challenges at night work zones, using red/white conspicuity tapes on equipment and barricades to prevent accidents.

- Logistics and transportation businesses must comply with DOT regulations, applying specific patterns of reflective tape on trailers to ensure visibility from all angles.

- Manufacturing facilities create safety pathways and highlight hazardous equipment with engineer-grade reflective tape that withstands industrial environments.

- Mining operations enhance worker safety in low-light conditions by marking evacuation routes with photoluminescent reflective tapes that function even during power failures.

- Emergency services vehicles maximize visibility during roadside operations with diamond-grade reflective materials that provide superior nighttime visibility.

- Forestry operations mark equipment and barriers in remote areas with weather-resistant reflective tapes designed to maintain performance despite exposure to extreme conditions.

High Visibility Strips and Their Daily Use Considerations

Everyday application of reflective strips requires attention to practical details that affect performance. Proper surface cleaning before application removes oils and contaminants that compromise adhesion strength. Temperature during installation significantly impacts immediate bond strength—most products require application above 50°F (10°C) for optimal results. Corner reinforcement prevents premature peeling at high-stress points. Users should avoid stretching during application as this creates internal tension that reduces longevity. Curved surfaces require special techniques or pre-cut segments to maintain proper adhesion. Regular cleaning with mild soap solutions removes road grime or workplace contaminants that diminish reflectivity. Small repairs should be addressed promptly before moisture penetrates damaged areas and compromises larger sections. Combining reflective elements with other safety equipment creates layered protection systems for comprehensive workplace safety.

Safety Marking Standards and Quality Indicators Every Buyer Should Know

Understanding reflective tape standards helps ensure compliance and performance. ASTM D4956 classifies reflective sheeting into different types based on brightness levels and intended applications. FMVSS 108 governs vehicle conspicuity requirements, mandating specific patterns and placement on commercial vehicles. ANSI/ISEA 107 addresses reflective components for high-visibility safety apparel requirements. Quality indicators include coefficient of retroreflection (measured in candelas per lux per square meter), which quantifies brightness performance. Reputable products provide detailed specification sheets listing reflectivity values, expected service life, and temperature tolerances. Look for certifications from recognized testing laboratories confirming compliance claims. Safety professionals recommend examining warranty terms as these often reflect manufacturer confidence in product durability. Integration with protective vests and other safety equipment should maintain required reflectivity standards when combined.

Reflective Material Investment and Value Assessment for Budget Planning

Reflective tape pricing varies significantly based on performance characteristics and intended applications. Engineer-grade materials offer economical solutions for basic applications with moderate visibility requirements. High-intensity and diamond-grade products command premium prices but deliver superior visibility distance and longer service life for critical safety applications. Roll length and width affect total coverage cost—larger projects benefit from bulk pricing on extended rolls. Installation expenses should factor into budgeting, especially for large-scale applications requiring professional application services. Long-term value assessment should consider replacement frequency based on exposure conditions—premium products often prove more economical when calculated over complete service life in demanding environments like welding areas. Regulatory non-compliance costs from insufficient reflective markings can include fines, increased liability, and potential project delays, making appropriate investment in quality materials financially prudent.

Quick Reflective Tape Selection Checklist

- Verify reflectivity grade meets minimum requirements for your specific application.

- Confirm weather resistance capabilities match your environmental exposure conditions.

- Measure application surfaces accurately to determine required tape width and length.

- Check surface compatibility with the adhesive type to ensure proper bonding.

- Calculate total visibility needs based on viewing distance and lighting conditions.

- Review compliance requirements for your industry and application type.

- Examine warranty terms to understand expected performance lifespan.

- Plan cleaning schedule based on environmental exposure conditions.

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

Engineer Reflective Tape | INCOM

INCOM Signs

$33.82 - $419.13Offers vibrant daytime visibility with reflective properties for nighttime Rated for a 7-year outdoor life span Adheres to almost any clean, dry, smooth surface Meets ASTM-D-4956 Type 1 Not intended for vehicle application$33.82 - $419.13 -

Conspicuity Tape (Red & White) 11''/ 7'' Pattern 2'' x 30'

INCOM Signs

$47.72Conspicuity Tape (Red & White) 11”/ 7” Pattern 2” x 30’ DOT-C2 reflective conspicuity tape exceeds requirements of the NHTSA (49 CFR 571), and every strip carries the DOT-C2 watermark certification for compliance...$47.72 -

Reflective Safety Hazard Stick-On Warning Tapes | Pioneer

Pioneer Workwear

$47.97Description This durable and weather-resistant warning tape effectively warns workers and pedestrians of unsafe or prohibited areas. Visual barricade tape blocks off designated areas For indoor and outdoor use Durable material resists accidental...$47.97 -

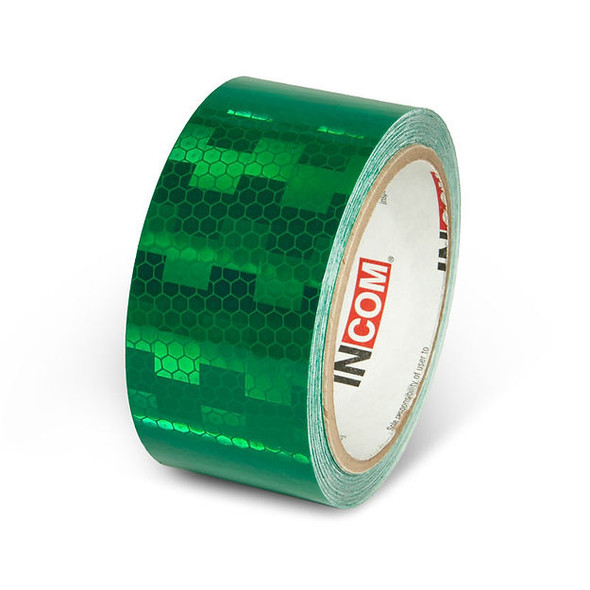

Green SuperBrite Reflective Tape | INCOM

INCOM Signs

$74.32 - $90.54Super Brite is an excellent choice for marking anything that requires a high level of night time visibility and longevity. The tape has an excellent entrance angularity and high intensity micro-prismatic surface. Aggressive adhesive system will adhere to...$74.32 - $90.54 -

Conspicuity Tape (2" x 18") 25/Pkg

INCOM Signs

$76.94Conspicuity Tape (2" x 18") 25/Pkg DOT-C2 reflective conspicuity tape exceeds requirements of the NHTSA (49 CFR 571), and every strip carries the DOT-C2 watermark certification for compliance. Modular pattern of reflective prisms allow it to...$76.94 -

Conspicuity Tape (Red & White) 11''/ 7'' Pattern 2'' x 150'

INCOM Signs

$204.57Conspicuity Tape (Red & White) 11”/ 7” Pattern 2” x 150’ DOT-C2 reflective conspicuity tape exceeds requirements of the NHTSA (49 CFR 571), and every strip carries the DOT-C2 watermark certification for compliance...$204.57 -

Conspicuity Tape (6"/6") 2" x 150'

INCOM Signs

$204.57Conspicuity (6"/6") 2" x 150' DOT-C2 reflective conspicuity tape exceeds requirements of the NHTSA (49 CFR 571), and every strip carries the DOT-C2 watermark certification for compliance. Modular pattern of reflective prisms allow it to be mounted...$204.57 -

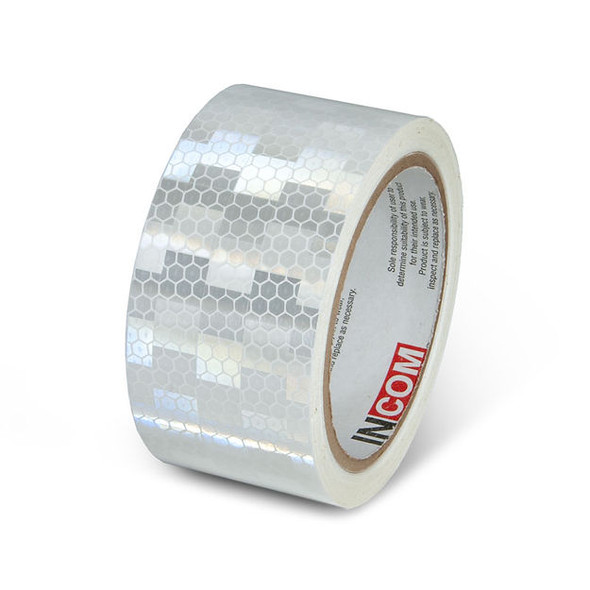

Conspicuity Tape (Solid White) 2'' x 150'

INCOM Signs

$228.56Conspicuity Tape (Solid White) 2” x 150’ DOT-C2 reflective conspicuity tape exceeds requirements of the NHTSA (49 CFR 571), and every strip carries the DOT-C2 watermark certification for compliance. Modular pattern of reflective prisms...$228.56 -

Conspicuity Tape (7"/11") 2" x 150'

INCOM Signs

$228.56Conspicuity Tape (7"/11") 2" x 150' DOT-C2 reflective conspicuity tape exceeds requirements of the NHTSA (49 CFR 571), and every strip carries the DOT-C2 watermark certification for compliance. Modular pattern of reflective prisms allow it to be...$228.56 -

Conspicuity Tape (Red & White) 6''/ 6'' Pattern 2'' x 150'

INCOM Signs

$230.13Conspicuity Tape (Red & White) 6”/ 6” Pattern 2” x 150’ DOT-C2 reflective conspicuity tape exceeds requirements of the NHTSA (49 CFR 571), and every strip carries the DOT-C2 watermark certification for compliance...$230.13 -

Engineer Grade Reflective Tape | INCOM

INCOM Signs

$405.79 - $437.18Engineer Grade Reflective Tape | INCOMTry our line of Engineer Grade Reflective Tapes. These tapes offer vibrant daytime visibility with reflective properties for nighttime use.All solid color tape is rated for use outdoors for a 7-year life span. Tape...$405.79 - $437.18 -

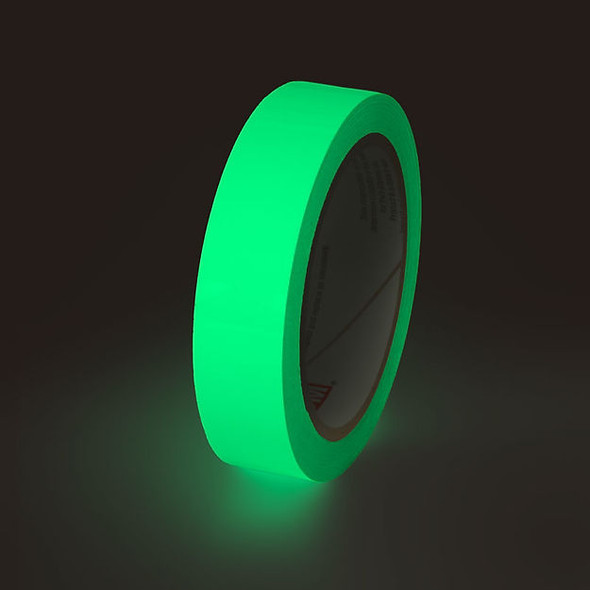

Glow-In-Dark Glow Marking Tape | INCOM

INCOM Signs

$406.30 - $461.16Glow-In-Dark Glow Marking Tape | INCOMGlow-in-the-Dark Tapes will GLOW" 6+ hours. This product comes with an aggressive permanent pressure sensitive adhesive that will adhere to most any clean, dry surface.Meets or Exceeds Standards:DIN 67510ASTM 2072ISO...$406.30 - $461.16 -

Glow Marking Tape | INCOM

INCOM Signs

$591.70 - $716.26Glow Marking Tape | INCOMGlow-in-the-Dark Tapes will , GLOW" 6+ hours. This product comes with an aggressive permanent pressure sensitive adhesive that will adhere to most any clean, dry surface.Meets or Exceeds Standards:DIN 67510ASTM 2072ISO 15370EU...$591.70 - $716.26 -

1" x 30' Glow-In-The-Dark Exit Tape | Pack of 12 | INCOM

INCOM Signs

$772.631" x 30' Glow-In-The-Dark Exit Tape | Pack of 12 | INCOM1" x 30'Our directional emergency exit tape is intended to be installed close to ground level, where a person would be crawling under smoke.Disclaimer: It is the sole responsibility of the...$772.63 -

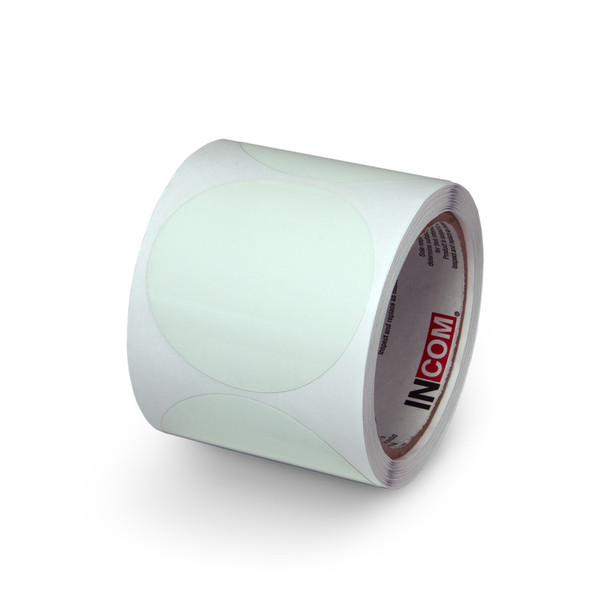

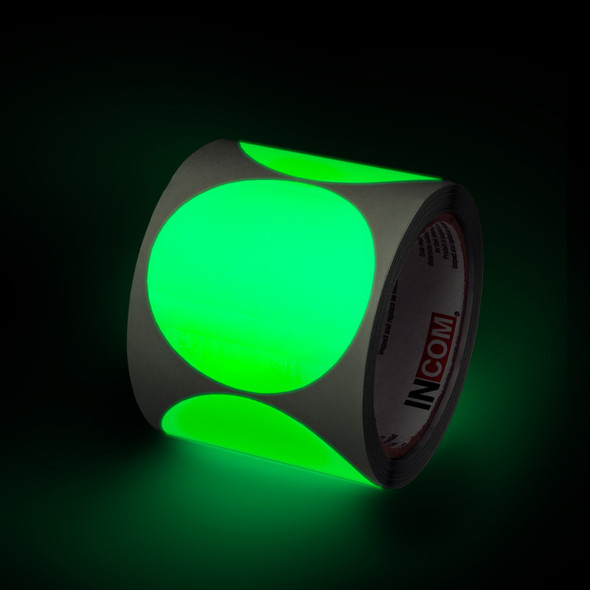

3" Glow-In-The-Dark Circles 100 per roll | Pack of 16 | INCOM

INCOM Signs

$2,142.433" Glow-In-The-Dark Circles 100 per roll | Pack of 16 | INCOM3" Dia.Our die cut arrows and dots can be used to further augment your escape routing program. All products are made from a premium safety grade photoluminescent material.Disclaimer: It is the...$2,142.43 -

2" x 150' Superbrite Reflective Tape | Pack of 8 | INCOM

INCOM Signs

$2,516.692" x 150' Superbrite Reflective Tape | Pack of 8 | INCOMSuperbrite is an excellent choice for marking anything that requires a high level of night time visibility, and a with a long term life cycle. The tape has an excellent entrance angularity and high...$2,516.69