Scaffolding Systems

What Are Scaffold Systems: Essential Safety Platforms

Scaffold systems are temporary elevated work platforms that provide safe access for construction, maintenance, and repair tasks. These modular structures typically consist of steel or aluminum frames, cross braces, and work platforms that can be assembled at various heights. All Safety serves construction professionals across Canada with comprehensive scaffold solutions and safety equipment for elevated work environments.

How Scaffold Systems Work and Function

Scaffold systems work by creating stable, level platforms using interlocking frame components and cross braces that distribute weight evenly. The basic assembly process involves connecting vertical frames with horizontal braces, then adding platform boards or decking. Most systems use pin connections or wedge locks to secure components together. Professional scaffold systems typically support significant loads when properly assembled and can reach considerable heights depending on the specific design and manufacturer specifications.

Key Benefits of Using Scaffold Systems

The primary benefits of scaffold systems include enhanced worker safety through stable platforms with guardrails, increased productivity compared to ladders, and versatile access to various work areas. These systems enable multiple workers to operate simultaneously while providing secure tool and material storage. All Safety recognizes that proper scaffold systems significantly reduce workplace accidents by eliminating unstable ladder positioning and providing consistent work surfaces.

Understanding Scaffold System Components

Essential scaffold components include base plates for level foundation contact, vertical standards that form the framework, ledgers that connect standards horizontally, and transoms that support the working platform. Platforms themselves consist of scaffold boards, steel planks, or aluminum decking designed to handle distributed loads. Safety components like guardrails, toe boards, and access ladders are typically required for platforms above certain heights according to safety regulations.

Professional vs Residential Scaffold Applications

Professional contractors typically use heavy-duty system scaffolds for commercial construction, industrial maintenance, and large-scale renovation projects. These systems often feature advanced components like adjustable base jacks, rolling casters, and specialized brackets for complex structures. Residential users generally need lighter-duty frame scaffolds for home maintenance, painting, and small repair projects that don't require the extensive capabilities of commercial systems.

When to Use Different Scaffold Types

Frame scaffolds work best for straightforward applications like exterior wall work, painting, and general maintenance tasks. System scaffolds are ideal for complex shapes, long-term projects, and situations requiring frequent reconfiguration. Rolling scaffolds provide mobility for indoor work or projects requiring frequent repositioning. Suspended scaffolds are necessary for high-rise building maintenance and situations where ground-based systems aren't practical.

Scaffold System Safety Requirements and Standards

Scaffold safety requirements typically mandate guardrails on platforms above specific heights, proper tie-offs to structures, and regular inspections by qualified personnel. Load capacity ratings must accommodate workers, tools, and materials without exceeding manufacturer specifications. All Safety emphasizes that proper training in scaffold assembly and use is essential for workplace safety compliance.

Common Scaffold Safety Features

Standard safety features include guardrail systems with top rails, mid rails, and toe boards to prevent falls and dropped objects. Base plates distribute loads across foundation surfaces, while adjustable legs accommodate uneven ground conditions. Many systems include integral ladder access and platform extensions to eliminate gaps between scaffold and work surfaces.

Limitations and Considerations for Scaffold Use

Key limitations of scaffold systems include weather restrictions during high winds or storms, ground conditions that may not support heavy loads, and height restrictions based on the specific system design. Setup time can be significant for complex configurations, and proper storage space is needed when not in use. Users must also consider ongoing inspection requirements and the need for qualified personnel to oversee assembly and modification.

Choosing the Right Scaffold System

Select scaffold systems based on maximum working height requirements, expected load capacity including workers and materials, and frequency of use for your specific applications. Consider whether you need mobility features like casters, special accessories for unique applications, and compatibility with existing safety equipment. The choice between rental and purchase typically depends on project duration and long-term usage patterns.

Scaffold Selection by Project Requirements

Residential projects often benefit from lightweight aluminum scaffolds that are easy to transport and assemble. Commercial construction typically requires heavier steel systems with higher load capacities and modular components for complex configurations. Industrial maintenance may need specialized scaffolds with features like spark-resistant materials or compatibility with overhead cranes.

Cost Considerations for Scaffold Systems

Scaffold costs vary significantly based on system type, height requirements, and rental versus purchase decisions. Basic frame scaffolds generally cost less than system scaffolds but offer fewer configuration options. Rental makes sense for short-term projects, while purchase becomes economical for frequent users or long-term applications. All Safety helps customers evaluate cost-effective scaffold solutions based on their specific project requirements and usage patterns.

Scaffold System Installation and Setup

Proper scaffold installation begins with site preparation including ground leveling and ensuring adequate load-bearing capacity. Assembly typically follows manufacturer specifications for component connections, bracing patterns, and tie-off requirements. Most systems require regular inspection during assembly and use to maintain safety standards.

Common Installation Challenges and Solutions

Uneven ground conditions can be addressed using adjustable base jacks or appropriate foundation materials like scaffold mud sills. Adequate tie-off points may require additional anchoring systems or guy wires depending on scaffold height and local wind conditions. Access issues can often be resolved through proper planning of platform layouts and ladder positioning.

Maintenance and Care Requirements

Regular scaffold maintenance includes inspection for damaged components, proper storage to prevent corrosion, and replacement of worn parts according to manufacturer recommendations. Components should be cleaned and properly stored between uses, with particular attention to connection points and adjustment mechanisms. Professional inspection services can help ensure ongoing safety compliance for frequently used scaffold systems.

Scaffold Quality and Performance Standards

Quality scaffold systems meet recognized industry standards for load capacity, material specifications, and safety features. Look for manufacturers that provide documentation of testing procedures, load ratings, and compliance certifications. Components should fit together precisely without excessive play or binding, and all safety features should function smoothly.

Identifying Quality Scaffold Components

Quality indicators include consistent manufacturing tolerances, proper galvanizing or protective coatings on steel components, and clear load capacity markings. Connections should engage positively without forcing, and all components should show evidence of proper quality control during manufacturing. Reputable manufacturers typically provide detailed assembly instructions and safety guidelines.

Troubleshooting Common Scaffold Issues

Common scaffold problems include instability due to inadequate bracing or poor foundation conditions, difficulty with component connections caused by damage or incorrect assembly, and platform issues like excessive deflection or gaps. Most problems can be prevented through proper initial setup and regular inspection procedures.

Maintaining Scaffold Safety and Performance

Address stability issues immediately by checking all connections, verifying proper bracing patterns, and ensuring adequate foundation support. Replace damaged components rather than attempting field repairs that may compromise safety ratings. When in doubt about scaffold condition or assembly, consult qualified personnel or the manufacturer's technical support resources.

Scaffold System Value and Investment

Scaffold systems represent a significant safety investment that can improve productivity and reduce workplace accidents when properly selected and maintained. The total cost of ownership includes initial purchase or rental costs, ongoing maintenance, storage requirements, and training expenses. Quality systems typically provide years of reliable service when properly cared for and can often be reconfigured for different applications.

Making Smart Scaffold Investment Decisions

Evaluate scaffold investments based on expected usage frequency, project types, and safety requirements rather than initial cost alone. Consider the long-term value of modular systems that can be reconfigured for different applications versus single-purpose designs. Factor in training costs, storage requirements, and ongoing maintenance when comparing options.

Essential Scaffold Selection Checklist

- Verify compliance with applicable safety standards and local regulations

- Confirm load capacity meets or exceeds your specific application requirements

- Ensure maximum height capability suits your typical project needs

- Check compatibility with existing safety equipment and procedures

- Consider rental versus purchase based on expected usage frequency

- Plan for adequate storage space and transportation requirements

- Budget for proper training and ongoing inspection requirements

- Evaluate manufacturer support and parts availability for long-term use

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

Pole Foot Aluminum Pump Jack

Werner

$19.45 - $68.13Pole Foot Aluminum Pump Jack | WernerThe PJ-PF-4 Aluminum Pump Jack Pole Foot is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Pole foot for aluminum poles Versatile, dependable, and easy to operate...$19.45 - $68.13 -

Pole Anchor Steel Pump Jack

Werner

$48.39The Pump Jack is designed for use with fabricated wood poles constructed of spliced 2x4's (up to 30' high) and accommodates two 2" x 10" wood planks with toe boards attached. Foot action does all the work needed to raise to position and a hand crank is...$48.39 -

Side Wall Staging Bracket Guardrail | Steel Construction | Guardian Fall Protection

Guardian Fall Protection

$132.50The Side Wall Staging Bracket Guardrail is required when a side wall staging bracket is installed higher than six feet off the ground. With its all steel construction, this product provides installation of guardrail, mid-rail, and toe board. FEATURES: ...$132.50 -

Side Wall Staging Bracket | Guardian Fall Protection

Guardian Fall Protection

$132.50The folding Side Wall Staging Bracket provides platform safety and convenience. This staging bracket is rated for two workers and additional 75 pounds of weight per 8' section. The bracket folds for compact storage and easy transportation. FEATURES ...$132.50 -

Rigid Support Brace Aluminum Pump Jack

Werner

$146.00Rigid Support Brace Aluminum Pump Jack | Werner The PJ-SBR Aluminum Pump Jack Rigid Support Brace is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Rigid support brace Versatile, dependable, and easy to...$146.00 -

Foldable Support Brace Aluminum Pump Jack

Werner

$146.00Foldable Support Brace Aluminum Pump Jack | Werner The PJ-SBF Aluminum Pump Jack Foldable Support Brace is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Foldable support brace Pivot points allow the brace...$146.00 -

Pole Connector Aluminum Pump Jack

Werner

$223.87Pole Connector Aluminum Pump Jack | Werner The PJ-PC Aluminum Pump Jack Pole Connector is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Easy to assemble Increase your working height by connecting aluminum...$223.87 -

Stacker Bracket Frame (38 3/4") | Durable Welded Steel | Guardian Fall Protection

Guardian Fall Protection

$230.05The Stacker Bracket Frame is the main support to the Stacker Bracket system; it's what your planks rest on and is the working surface. The frame itself is composed of durable welded steel and is great for eaves up to eighteen inches (18") in size. The...$230.05 -

Workbench Aluminum Pump Jack

Werner

$233.60Workbench Aluminum Pump Jack | Werner The PJ-WB Aluminum Pump Jack Workbench is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Workbench for aluminum pump jack systems Versatile, dependable, and easy to...$233.60 -

Wall Jack | Guardian Fall Protection

Guardian Fall Protection

$256.53Description The Wall Jack is used to raise walls and beams and tighten flooring and decking. Made of heavy duty, malleable cast iron, the wall jack rides up and down on a 2-by-4-foot pole, working like a car jack for dozens of construction uses. To lift...$256.53 -

Aluminum Pump Jack Pole

Werner

$272.54 - $1,022.02Aluminum Pump Jack Pole | Werner The Aluminum Pump Jack Pole is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Durable design for all types of weather, rated for up to 50ft working heights Industry...$272.54 - $1,022.02 -

Narrow End Rail Kit Aluminum Pump Jack

Werner

$350.41Narrow End Rail Kit Aluminum Pump Jack | WernerThe Aluminum Pump Jack Narrow End Rail Kit is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Easy to assemble Wide version is also available Style: Aluminum...$350.41 -

Wide End Rail Kit Aluminum Pump Jack

Werner

$387.20Wide End Rail Kit Aluminum Pump Jack | Werner The Aluminum Pump Jack Narrow End Rail Kit is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Easy to assemble Wide version is also available Style: Aluminum...$387.20 -

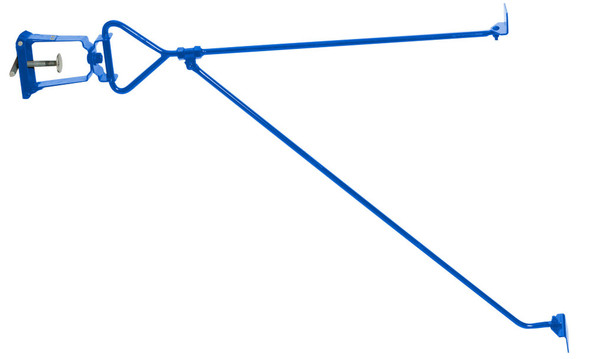

Wall Brace | Guardian Fall Protection

Guardian Fall Protection

$389.24Wall Brace | Guardian Fall Protection Compliance: OSHA 1910, OSHA 1926 Subpart M Compliance: This product meets the following regional compliance standards OSHA 1910.140 OSHA 1926.502$389.24 -

Aluminum Pump Jack

Werner

$438.01Aluminum Pump Jack | Werner The PJ-100 Aluminum Pump Jack is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Aluminum frame Z channel is 20% stronger than leading competitor Large boot strap and slip...$438.01 -

Safety Net Aluminum Pump Jack

Werner

$730.01Safety Net Aluminum Pump Jack | Werner The PJ-SN Aluminum Pump Jack Safety Net easily attaches to your stage to prevent debris and tools from falling to the ground. Durable nylon material meets OSHA requirements and can be used as fall protection. ...$730.01