Replacement Window

What Are Replacement Windows: Essential Face Protection Components

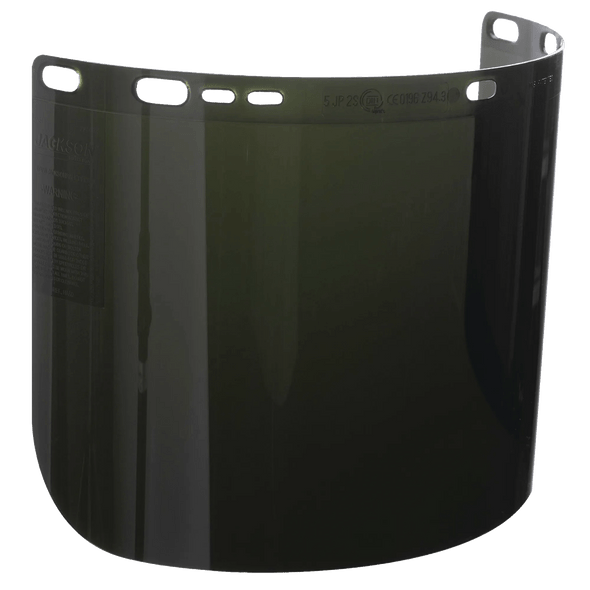

Replacement windows are transparent or mesh protective barriers designed to attach to face shield holders or helmets, providing eye and face protection from workplace hazards. These protective components serve as the primary barrier between potential dangers and a worker's face, offering defense against flying debris, chemical splashes, impacts, and radiation. Replacement windows typically consist of materials like polycarbonate, PETG (polyethylene terephthalate glycol), or metal mesh in various configurations. Industrial workers, welders, laboratory technicians, forestry workers, and manufacturing personnel rely on these protective components to maintain safety compliance while preserving visibility during hazardous operations.

Key Takeaways About Replacement Windows for Safety Equipment

- Replacement windows provide critical protection against flying debris, chemical splashes, and impacts in hazardous work environments.

- Materials like polycarbonate offer superior impact resistance while PETG provides excellent chemical resistance for different workplace applications.

- Regular inspection of replacement windows ensures continued protection and compliance with safety regulations.

- Different industries require specific types of replacement windows based on their particular hazards and visibility needs.

- Proper thickness selection balances durability with comfort and optical clarity for workers.

- Window binding (bound vs. unbound edges) affects durability, performance, and compatibility with different face shield holders.

- Understanding certification standards like ANSI Z87.1 helps ensure adequate protection levels for specific workplace hazards.

Common Applications and Use Cases for Protective Face Shield Windows

Replacement windows serve various critical applications across multiple industries. In manufacturing settings, these protective components shield workers from flying metal shards, wood chips, and chemical splashes. Medical professionals rely on face shields with clear windows for infection control and fluid protection. Construction workers benefit from impact-resistant windows that protect against debris while maintaining visibility in bright conditions. Forestry operations use mesh variants to prevent wood chips and sawdust injuries while allowing airflow. Chemical processing facilities require windows with chemical resistance properties. Even food processing workers utilize these components to maintain hygiene standards while protecting against splashes from cleaning agents and processing materials.

How to Choose the Right Replacement Window for Maximum Protection

Selecting the appropriate replacement window requires careful consideration of several factors. First, identify the specific hazards present in your work environment—impact threats require polycarbonate materials, while chemical exposure necessitates PETG construction. Evaluate the required level of optical clarity based on task precision, with clear polycarbonate offering superior visibility for detailed work. Consider thickness requirements, typically ranging from 0.035" to 0.060", with thicker materials providing greater protection. Compatibility with existing face shield holders or helmets is essential for proper fit and function. Anti-fog coatings prove valuable in humid environments. Industry experts recommend selecting windows that exceed minimum safety standards for your specific application rather than meeting baseline requirements.

Essential Replacement Window Features Explained: What You Need to Know

Critical features of replacement windows significantly impact performance and protection levels. Material composition determines resistance properties, with polycarbonate excelling in impact scenarios while PETG offers superior chemical resistance. Thickness directly correlates with protection level—thicker windows provide enhanced protection but may add weight. Edge treatment (bound vs. unbound) affects durability and compatibility with holders. Optical clarity impacts visibility and eye strain during extended use. Coating applications like anti-fog or anti-scratch enhance performance in specific conditions. Shape configuration (flat vs. formed) influences field of vision and face coverage. UV protection prevents eye damage during outdoor use. Special tints for welding or bright light exposure protect against eye hazards while maintaining visibility.

Industry-Specific Applications for Face Shield Replacement Windows

- Construction - Building sites expose workers to flying debris and dust, requiring high-impact polycarbonate windows with adequate thickness and wide coverage to protect facial areas while maintaining visibility in variable lighting conditions.

- Healthcare - Medical facilities need clear, distortion-free windows with anti-fog properties and chemical resistance to protect against bodily fluids while allowing precise work and preventing cross-contamination during procedures.

- Manufacturing - Factory environments feature mechanical hazards necessitating impact-resistant windows with peripheral protection and sometimes specialized coatings for specific processes like welding or metalwork.

- Chemical Processing - Plants handling corrosive materials require PETG windows with chemical resistance properties and full-face coverage design to prevent splash exposure while ensuring workers can clearly read gauges and control panels.

- Forestry - Logging operations benefit from mesh replacement windows that prevent wood chips and debris injuries while allowing maximum airflow to prevent overheating and fogging during physical labor.

- Food Processing - These facilities need transparent, easy-to-sanitize windows that resist cleaning chemicals while providing splash protection and maintaining hygiene standards required for food safety compliance.

Professional and Industry Usage: Face Protection Standards Across Sectors

Professional usage of replacement windows varies significantly across industries. Welders require specialized green or shade-rated windows that filter harmful light while maintaining visibility of the weld pool. Laboratory technicians prioritize chemical resistance and optical clarity for precise procedures. Construction safety protocols often mandate impact-resistant windows with peripheral protection. Medical professionals need windows that withstand repeated disinfection without degrading. Manufacturing facilities maintain compliance logs tracking window condition and replacement schedules. Industry-specific requirements often exceed general safety standards, with specialized certifications for particular sectors. Professional users typically receive specific training on visual inspection protocols to identify when replacement is necessary based on scratches, discoloration, or impact damage.

Daily Use and Practical Considerations for Face Shield Visors

Everyday usage of replacement windows presents several practical considerations. Workers must regularly inspect windows for scratches, cracks, or discoloration that compromise protection. Proper cleaning procedures using compatible solutions prevent damage to protective coatings and maintain clarity. Storage between uses significantly impacts longevity—windows should be stored flat and protected from UV exposure. The weight and comfort of the window affect user compliance during extended wear periods. Ventilation factors and anti-fog properties become crucial in humid environments or during physical exertion. Some environments require frequent replacement due to abrasive conditions or chemical exposure. Workers should understand installation procedures to ensure proper mounting without creating stress points that could compromise the window during impact.

What Are Safety Standards for Protective Face Visors: Complete Guide

Replacement windows must adhere to rigorous safety standards to ensure adequate protection. ANSI Z87.1 in North America establishes baseline requirements for eye and face protection, including impact resistance testing. CSA Z94.3 provides Canadian specifications for eye and face protectors in workplace environments. EN 166 offers European standards with specific markings indicating protection levels. The International Safety Equipment Association certification serves as an additional quality indicator. Windows must feature permanent markings indicating compliance with applicable standards. Many industries require specific certifications beyond these baseline standards—arc flash protection requires windows meeting NFPA 70E requirements. Safety professionals recommend selecting windows that exceed minimum requirements relevant to specific workplace hazards rather than meeting baseline specifications.

Investment Considerations When Selecting Shield Replacement Parts

When evaluating replacement windows from an investment perspective, several factors impact total cost of ownership. Initial price ranges from $3-$40 depending on material quality, thickness, and special features. Premium options with anti-fog, anti-scratch, or specialized coatings command higher prices but typically offer extended service life. Replacement frequency significantly impacts annual costs—budget options may require replacement every 2-3 months in harsh environments while premium windows often last 6-12 months under similar conditions. Compatibility with existing headgear affects overall equipment costs. Many organizations implement tiered purchasing strategies, utilizing premium windows for specialized high-risk roles while employing standard options for general applications. The cost of non-compliance through inadequate protection typically far exceeds any savings realized through purchasing inferior products.

Quick Selection Checklist for Replacement Windows

- Verify the window meets ANSI Z87.1 or CSA Z94.3 standards for your application.

- Check compatibility with your specific face shield holder or helmet model.

- Measure the required dimensions and thickness for proper coverage and protection.

- Select appropriate material based on specific workplace hazards.

- Calculate total annual cost based on replacement frequency and initial price.

- Consider worker comfort factors that impact compliance and productivity.

- Inspect for proper markings indicating certification and protection levels.

- Establish a regular inspection and replacement schedule for all windows.

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

P/C Clear (20cm/7.87")

Hellberg

$15.73Suitable for: Physical Distance, Grinding, Construction, Industrial work, Metal work$15.73 -

$16.18

$16.18 -

MAXVIEW Replacement Visor PC | Jackson Safety

Jackson Safety

$16.81 - $39.58Description Replacement polycarbonate windows for Maxview™ Series Face Shield System. Fits models 14200 14201 14202 and 14203. Model 14214 uncoated polycarbonate replacement window Model 14215 anti-fog polycarbonate replacement window Provides...$16.81 - $39.58 -

Replacement Window for 390 Series Face Shield - Uncoated

Sellstrom

$17.08Description Sellstrom® 390 Series Premium replacement face shield windows come in a variety of sizes shades and coatings to meet a wide range of industrial applications. Product Description: Replacement window for Sellstrom 390 Series face...$17.08 -

$17.64

$17.64 -

F20 PC Face Shield Visor Mold Clear 8"x15.5"x0.060" Bnd Shp B | Jackson Safety

Jackson Safety

$18.40Description Jackson Safety polycarbonate face shield windows are designed to offer premium protection from flying debris and high heat work applications. They are ideal for a wide range of heavy industrial manufacturing applications. Provides ideal...$18.40 -

Replacement Window for 390 Series Face Shield | Sellstrom

Sellstrom

$22.61Description Sellstrom® 390 Series Premium replacement face shield windows come in a variety of sizes shades and coatings to meet a wide range of industrial applications. Product Description: Replacement window for Sellstrom 390 Series face...$22.61 -

Faceshield - Formed Shade Polycarbonate - 8x15.5"

WASIP

$23.94Faceshield - Formed Shade Polycarbonate - 8x15.5" | WASIPMolded from high-strength polypropionate, polycarbonate or PCTGProvides frontal and lateral protectionEasy to attach to headgear and bracketAvailable in .060"/.080" thicknessPackaging: 50/Case$23.94 -

Replacement Window for 380 Series Face Shield | Sellstrom

Sellstrom

$26.33 - $97.07Description Sellstrom® 380 Series Replacement Dual Crown Face Shield Windows are scratch-resistant and extra-wide to fit all facial contours ensuring reliable protection from splashes particles and flying debris. Featuring a non-glare finish for...$26.33 - $97.07 -

$27.99

$27.99 -

Acetate Clear Anti-Fog (20cm/7.87")

Hellberg

$27.99Suitable for: Physical Distancing, Chemical splash, Manufacturing, Food Processing$27.99 -

Universal Fit PETG Safety Visor | 10/Pack | Dynamic

Dynamic Safety

$29.52 - $50.40Face shield CLEAR Die cut visor 8X 15 ® P.E.T.G. co polyester 0.40 in /1.0 mm$29.52 - $50.40 -

P/C Clear w/ Chinguard (20cm/7.87")

Hellberg

$31.39Suitable for: Physical Distance, Grinding, Construction, Industrial work, Metal work$31.39 -

$31.39

$31.39 -

F50 PC Face Shield Visor CLR 8"x15.5"x0.060" Unbd Shp B | Jackson Safety

Jackson Safety

$37.89Description Polycarbonate IRUV face shields provide protection from infrared and ultraviolet radiation as well as flying debris chemical splash and high heat work applications. Universal Pin Pattern Mounting System allows use with most brands of...$37.89 -

Etched Stainless Steel Mesh (20cm/7.87")

Hellberg

$38.61Suitable for: Forestry work, Landscaping work.$38.61