Tuff Built

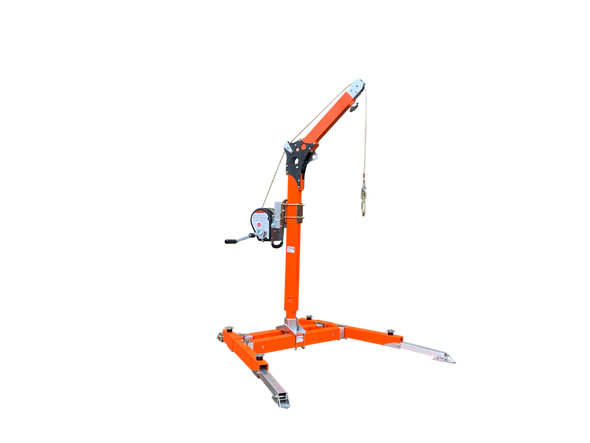

Complete Davit System Kit | Floor Mount | Tuff Built

- SKU:

- 30104/30108/30048/60686/10983/10981CSA

Description

PRO-3 Series Upper Mast; 28R-54H

The PRO-3 Series Upper Mast; 28R-54H | Tuff Built 30104 refers to a specific piece of equipment that likely belongs to the category of telecommunications, construction, or utility poles. While I don't have an exact match for a product named this specific combination, based on the name and industry standards, I can break down the potential components and their significance:

1. PRO-3 Series:

This could represent a particular line or series of masts/poles designed for heavy-duty use. The "PRO" prefix usually signifies a professional-grade product, often engineered for enhanced performance, durability, and reliability. The “-3” could indicate a specific version or iteration within the series.

PRO Series masts are often used for telecommunication towers, industrial applications, or even for crane operations, offering a high level of support and strength.

2. Upper Mast:

An upper mast is generally the upper portion of a mast structure, used to hold equipment like antennas, cameras, or lighting. It is built to withstand harsh environmental conditions (e.g., wind, rain, snow). The upper section is designed to be stronger and more stable because it bears the majority of the weight or stress at higher elevations.

3. 28R-54H:

These numbers likely refer to specifications of the mast:

28R could indicate the mast's diameter (in inches or millimeters) or height (possibly 28 feet or meters).

54H might denote the height of the upper mast section, potentially 54 feet or meters, and "H" could imply height or even horizontal dimensions.

This specification is critical for determining how much weight and load the mast can bear, as well as its suitability for different applications like cellular communication, broadcasting, or even industrial uses.

Key Features (Possible):

Durability & Strength: Likely constructed from high-grade steel or aluminum for weather resistance and strength, capable of withstanding harsh environments.

Weight Capacity: Designed to support heavy equipment like antennas, radio transmitters, or other infrastructure necessary for telecommunication.

Height: A crucial feature for communication towers, ensuring the upper section reaches an appropriate level for signal coverage.

Modular Design: Can be part of a larger modular system, allowing for easier upgrades or replacements in the future.

Applications:

Telecommunications Towers: Used to hold antennas for 5G, 4G, radio, or satellite communication.

Industrial Structures: Could also be used in construction, crane operations, or heavy-duty industrial settings.

Lighting and Signage: Also used for holding large signage or lights in open areas, including parking lots, roads, or industrial zones.

PRO-3 Series Lower Mast; 40"; for 30104 & 30105

Overview:

The PRO-3 Series Lower Mast is designed to work with specific Tuff Built equipment models 30104 and 30105, enhancing the operational range and strength of these lifting or construction machines. It is built with durability, precision, and safety in mind, suitable for various industrial applications.

Key Specifications:

-

Model: PRO-3 Series Lower Mast

-

Height: 40 inches (for the lower mast section)

-

Compatibility: Designed for Tuff Built models 30104 and 30105

-

Material: High-strength steel or other heavy-duty materials, ensuring durability in tough environments

-

Finish: Typically powder-coated or treated for corrosion resistance

-

Load Capacity: The load capacity may vary depending on the application, but the mast is designed to handle significant weight loads for lifting or positioning tasks.

Features:

-

Heavy-Duty Construction:

-

Made from high-strength steel to withstand heavy loads and rough conditions.

-

Durable finish to prevent corrosion and wear over time, ensuring long-lasting use in outdoor or industrial settings.

-

-

Precision Engineering:

-

Designed to fit perfectly with Tuff Built models 30104 and 30105, ensuring smooth operation and safety.

-

Adjustable or modular design for various height configurations, depending on your specific lifting or positioning needs.

-

-

Versatility:

-

Can be used in various construction, material handling, and rigging applications.

-

Ideal for use in environments where heavy lifting and positioning equipment are required.

-

-

Safety Features:

-

Safety locks and other mechanisms are often integrated to prevent accidental slippage or malfunction.

-

Designed to meet industry safety standards.

-

-

Ease of Maintenance:

-

Requires minimal maintenance with proper care due to the high-quality material and construction.

-

Components are designed to be easy to clean and inspect for wear.

-

Dimensions:

-

Length: As specified by the 40" measurement for the lower mast section.

-

Diameter/Width: Specific dimensions can depend on the configuration and intended use, but Tuff Built equipment typically uses standard sizing compatible with a range of accessories.

Applications:

-

Construction sites for heavy lifting and positioning of materials.

-

Rigging systems where mast height and stability are critical.

-

Material handling and storage solutions requiring precision placement.

Additional Notes:

-

It's always important to check the manufacturer's guidelines for installation instructions and recommended maintenance schedules.

-

If you're using this with specific Tuff Built equipment like models 30104 and 30105, always verify compatibility with your equipment's manual to ensure optimal performance.

Conclusion:

The PRO-3 Series Lower Mast is a robust, reliable accessory for Tuff Built equipment, offering excellent lifting capability, durability, and safety features. Make sure to check the precise specifications for your models (30104 & 30105) to ensure perfect fit and performance.

Floor Mount Base (Mild Steel, Hot Dip Galvanized)

1. Product Overview:

-

Material: Mild Steel

-

Finish: Hot Dip Galvanized

-

Primary Function: Used for securing structures or equipment to the floor, commonly in industrial and commercial applications.

2. Material Specifications:

-

Base Material: Mild Steel (Carbon steel, typically ASTM A36 or equivalent)

-

Properties: Low-carbon content (~0.05% to 0.25%) for easier fabrication, good ductility, and weldability.

-

Yield Strength: Typically 250-400 MPa (Mega Pascal)

-

Tensile Strength: Around 400-550 MPa, depending on grade and processing.

-

3. Galvanizing Process:

-

Hot-Dip Galvanizing:

-

A process where steel is dipped into molten zinc at approximately 450°C (850°F) to form a protective layer.

-

Coating Thickness: Typically between 50-100 microns (0.05mm to 0.1mm) depending on product size.

-

Corrosion Resistance: Highly resistant to environmental factors such as water, salt, and humidity, ensuring extended lifespan, especially for outdoor and marine environments.

-

Longevity: Zinc coating can last up to 50+ years in certain environments before noticeable corrosion begins.

-

4. Dimensions:

-

Base Plate Dimensions:

-

Length: Typically between 150 mm (6") and 300 mm (12") depending on the model.

-

Width: Similar to length, typically 150 mm (6") to 300 mm (12").

-

Height: Generally between 100 mm (4”) and 200 mm (8”) from base plate to top of mounting column.

-

Mounting Holes: 4 to 6 holes (typically 12 mm - 20 mm in diameter) for securing bolts, depending on load requirements and design specifics.

-

-

Hole Spacing: Distances between holes vary, typically 50 mm (2") to 100 mm (4") center-to-center.

5. Load Capacity:

-

Weight Bearing: Floor mount bases like the Tuff Built 30048 are generally rated to handle heavy loads (typically up to 2 tons or 4,000 lbs), but exact specifications depend on the model.

-

Load Distribution: Ensures even load distribution across the mounting surface, preventing stress concentration in any single area.

-

For more precise weight ratings, it's recommended to consult the technical datasheet or the manufacturer.

-

6. Installation:

-

Mounting: The base is designed to be anchored to a concrete or other solid surface using heavy-duty bolts or anchors.

-

Anchor Type: Expansion bolts, wedge anchors, or chemical anchors are often used.

-

Installation Method: Typically, the base plate is bolted down to a concrete slab or floor, ensuring a solid, non-movable foundation.

-

Drilling Requirements: If anchoring to concrete, ensure holes are drilled to the proper depth and diameter for the anchor bolts.

-

7. Applications:

-

Primary Use: Mounting poles, posts, or structural supports to the floor for industrial, commercial, or outdoor use.

-

Common in telecommunications, street lighting, fencing, utility poles, and sign installations.

-

-

Industries:

-

Construction: For securing posts or frames.

-

Telecommunications: To secure antennas or radio towers.

-

Utilities: For power and communications poles.

-

Fencing: For mounting fence posts in outdoor, high-corrosion environments.

-

Street & Area Lighting: Used for light poles or security lights in outdoor environments.

-

8. Corrosion Resistance:

-

The hot-dip galvanization provides superior protection in harsh conditions.

-

Rust Resistance: The coating offers long-term protection against rust, especially in areas exposed to moisture, salts, or acids.

-

Weather Resistance: Well-suited for use in all climates, including coastal or industrial areas with high corrosion potential.

-

9. Certifications and Standards:

-

Galvanization Standard:

-

ISO 1461: Standard for hot-dip galvanized coatings on iron and steel.

-

ASTM A123: Standard specification for zinc coatings applied by the hot-dip process.

-

10. Environmental Impact & Sustainability:

-

Recyclability: Both the mild steel and galvanized coating are recyclable, contributing to environmental sustainability.

-

Longevity: The hot-dip galvanizing process significantly extends the lifespan of the base, reducing the need for frequent replacements and maintenance.

11. Weight:

-

Approximate Weight: The weight of the base will vary based on the size of the model. Typical weights range from 10 kg (22 lbs) to 50 kg (110 lbs) for larger bases.

12. Safety Considerations:

-

Handling: The base should be handled with care to avoid sharp edges (which may be present depending on the cutting process) and to prevent any injury during installation.

-

Corrosion: Ensure the galvanized coating remains intact during installation; damage to the coating may lead to localized corrosion.

13. Packaging and Shipping:

-

Packaging: Typically packed in cardboard or wooden crates for shipping. Some products may include plastic or foam padding for additional protection.

-

Shipping Size: Expect packaging to vary based on the size of the base. Larger bases may be shipped via palletized freight.

Conclusion:

The Tuff Built 30048 Floor Mount Base is a high-quality, corrosion-resistant, and durable foundation solution for various commercial and industrial applications. Its mild steel construction with a hot-dip galvanized finish ensures long-lasting performance, even in tough environments.

3-Way Tri-pod Bracket for use with Arco-Pod.

The 3-Way SRL Bracket allows for the attachment of the Guardian Fall Protection 3-Way SRL to the Arc-O-Pod tripod.

- Perfect for use in confined space applications, the 3-Way SRL functions as both a standard SRL, and as a rescue/retrieval winch in the event of a fall.

COMPLIANCE

This product meets the following regional compliance standards

-

ANSI Z359.1-07

-

ANSI A10.32-12

-

OSHA 1926 Subpart M

-

OSHA 1910

Instruction Manual

https://s3-us-west-2.amazonaws.com/catsy.672/85083__Rev._D__15030_Arc_O_Pod_small.pdf

Test Report

https://s3-us-west-2.amazonaws.com/catsy.672/10974+Customer+Facing+Report+WEB.pdf

Metal Housing w/ 3/16" Galvanized Cable, Swivel Top, Steel Snap Hook

Description

An SRL designed both for standard use and for post-fall worker recovery

A reality of the world of fall protection is that, no matter how much effort is put towards preventing them, falls still sometimes happen. This is why it is mandatory to have an extensive rescue plan at every jobsite. The 3-Way Rescue and Retrieval SRL can plan a central role in such plans. In the event of a fall, it can be used to raise or lower the user to the next closest safe working platform.

Features

- Carabiner included

- Swivel top connection point and swivel snap hook help reduce lifeline snagging or tangling

- Integral rubber lifeline stopper doubles as a convenient hand grip

- Integral rubber lifeline stopper doubles as a convenient hand grip

- Ergonomic carrying handle for more convenient transport around the job

- Switch between standard SRL mode and rescue/retrieval mode with easy to use adjustment knob

- Lifeline Length: 65'

Downloads

Compliance

This product meets the following regional compliance standards

- OSHA 1910.140

- OSHA 1926.502

- ANSI Z359.14

- CSA Z259.2.2

![Davits [2] w/Anchar Points [2] | Tuff Built | All Safety Davits [2] w/Anchar Points [2] | Tuff Built | All Safety](https://cdn11.bigcommerce.com/s-oizklbqtoh/images/stencil/590x590/products/11017/37759/20014__17877.1767671211.jpg?c=1)