Werner

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

2-Man Stage

Werner

$564.54 - $2,530.712-Man Stage | Werner The Scaffold Stage with a 500lb duty rating that allows for 2 people on one plank. The Twist-Proof® stage design is ideal for ladder jack applications, swing stages or...$564.54 - $2,530.71 -

Aluminum Pump Jack

Werner

$438.01Aluminum Pump Jack | Werner The PJ-100 Aluminum Pump Jack is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Aluminum frame Z channel is 20% stronger...$438.01 -

Aluminum Pump Jack Pole

Werner

$272.54 - $1,022.02Aluminum Pump Jack Pole | Werner The Aluminum Pump Jack Pole is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Durable design for all types of...$272.54 - $1,022.02 -

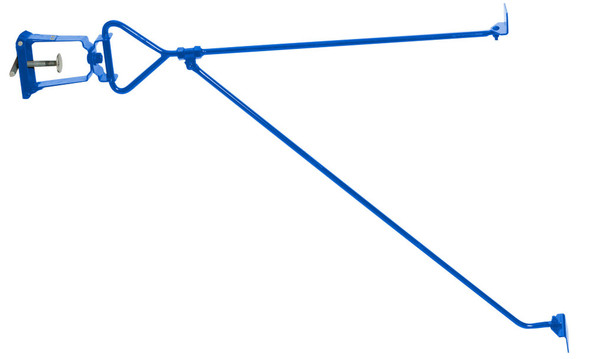

Foldable Support Brace Aluminum Pump Jack

Werner

$146.00Foldable Support Brace Aluminum Pump Jack | Werner The PJ-SBF Aluminum Pump Jack Foldable Support Brace is a field-replaceable component for nestable stages. Versatile, dependable, and easy to...$146.00 -

Narrow End Rail Kit Aluminum Pump Jack

Werner

$350.41Narrow End Rail Kit Aluminum Pump Jack | WernerThe Aluminum Pump Jack Narrow End Rail Kit is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Easy to...$350.41 -

Nestable 2-Man Stage

Werner

$846.81 - $2,044.04Nestable 2-Man Stage | WernerThe aluminum Nestable Stage. The handles nest inside of each other to minimize gaps between walkways providing a consistent rail depth regardless of stage length,...$846.81 - $2,044.04 -

Pole Anchor Steel Pump Jack

Werner

$48.39The Pump Jack is designed for use with fabricated wood poles constructed of spliced 2x4's (up to 30' high) and accommodates two 2" x 10" wood planks with toe boards attached. Foot action does all the...$48.39 -

Pole Connector Aluminum Pump Jack

Werner

$223.87Pole Connector Aluminum Pump Jack | Werner The PJ-PC Aluminum Pump Jack Pole Connector is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Easy to...$223.87 -

Pole Foot Aluminum Pump Jack

Werner

$19.45 - $68.13Pole Foot Aluminum Pump Jack | WernerThe PJ-PF-4 Aluminum Pump Jack Pole Foot is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Pole foot for aluminum...$19.45 - $68.13 -

Rigid Support Brace Aluminum Pump Jack

Werner

$146.00Rigid Support Brace Aluminum Pump Jack | Werner The PJ-SBR Aluminum Pump Jack Rigid Support Brace is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. ...$146.00 -

Safety Net Aluminum Pump Jack

Werner

$730.01Safety Net Aluminum Pump Jack | Werner The PJ-SN Aluminum Pump Jack Safety Net easily attaches to your stage to prevent debris and tools from falling to the ground. Durable nylon material meets OSHA...$730.01 -

Wide End Rail Kit Aluminum Pump Jack

Werner

$387.20Wide End Rail Kit Aluminum Pump Jack | Werner The Aluminum Pump Jack Narrow End Rail Kit is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Easy to...$387.20 -

Workbench Aluminum Pump Jack

Werner

$233.60Workbench Aluminum Pump Jack | Werner The PJ-WB Aluminum Pump Jack Workbench is a field-replaceable component for nestable stages. Versatile, dependable, and easy to operate. Workbench for aluminum...$233.60

Werner Scaffolding & Pump Jack Equipment: Complete Shopping Guide for All Types and Price Points

Werner scaffolding systems cost $146-$2,530 and protect construction workers from falls during elevated work. Entry-level pump jack accessories start at $19, professional-grade 2-man stages from $564, meeting OSHA requirements with 5-10 year typical lifespan depending on use intensity and maintenance schedules.

You'll typically find Werner pump jack systems in commercial construction, residential siding projects, and maintenance work. The reality is these systems handle workers up to 250 pounds per platform section. Professional contractors choose Werner for consistent weight distribution and modular expansion capabilities.

Werner Pump Jack Systems for Different Project Types

Aluminum pump jacks cost $438 for basic units, while 2-man stages range $564-$2,530 depending on platform length. Steel components offer higher durability but won't protect against aluminum's corrosion resistance in outdoor environments.

Here's what matters most for project planning: pump jack poles cost $272-$1,022 based on height requirements. Contractors typically need 6-foot sections for single-story work, 12-18 foot sections for two-story projects, and 24-foot sections for commercial applications.

| Equipment Type | Price Range | Weight Capacity | Typical Lifespan |

|---|---|---|---|

| Basic Pump Jack | $438 | 250 lbs | 8-10 years |

| 2-Man Stage (12-16ft) | $564-$846 | 500 lbs | 10-12 years |

| Nestable Stage (20-24ft) | $1,400-$2,530 | 500 lbs | 12-15 years |

| Support Accessories | $19-$730 | Varies | 5-8 years |

| Pump Jack Poles | $272-$1,022 | 500 lbs | 15-20 years |

Key Takeaways About Werner Scaffolding Equipment

- Werner scaffolding costs $146-$2,530 and typically lasts 8-15 years with proper maintenance and storage

- Pump jack systems protect against falls but require replacement when weight capacity decreases or structural damage appears

- 2-man stages handle 500-pound capacity but won't protect against overloading beyond manufacturer specifications

- Aluminum components resist corrosion for 10+ years while steel accessories need annual rust inspection

- Professional installations require OSHA-compliant setup and costs 15-25% more than basic residential configurations

- Nestable stages reduce storage space by 40% but cost $280-$486 more than standard platforms

- Replacement parts availability spans 15+ years though discontinued models may need custom fabrication

How to Choose Werner Scaffolding for Your Specific Work Environment

Select Werner scaffolding based on: platform length (12-24 feet), weight capacity requirements (250-500 pounds), and setup frequency (daily vs project-based). Commercial contractors need nestable systems for transport efficiency, while residential projects use standard stages for cost savings.

Here's the thing about scaffolding selection: aluminum pump jacks work best for exterior painting and siding installation. Steel components handle heavy masonry work but require more maintenance in humid conditions. You'll typically find 16-20 foot platforms optimal for most residential applications.

Construction Site Requirements by Industry Type

Residential contractors need basic pump jack systems rated for 250-pound capacity per worker position. Commercial projects require 500-pound rated platforms with full body fall protection harnesses and guardrail integration capabilities.

The reality is OSHA requires guardrails on platforms over 6 feet height. Werner systems accommodate standard guardrail attachments, though you'll need separate guardrail system components for full compliance.

Platform Size Selection Based on Worker Count

Single-worker platforms need 12-16 foot sections for material storage and movement. Two-worker setups require 20-24 foot platforms with center support bracing. Larger crews won't work efficiently on single platforms and need multiple pump jack installations.

Height Requirements and Pole Configuration

Standard residential work uses 12-18 foot poles for single and two-story access. Commercial applications need 24+ foot configurations with pole connectors every 12 feet. Higher installations require engineered calculations and professional setup oversight.

- Measure maximum working height plus 3-foot safety margin for pole selection

- Calculate total worker and material weight for capacity requirements

- Determine daily setup frequency for aluminum vs steel component choice

- Assess transport requirements for nestable vs standard platform selection

- Review OSHA compliance needs for guardrail and fall protection integration

- Plan storage space requirements for off-season equipment protection

- Budget for required accessories like safety nets and support braces

Werner Scaffolding Lifespan: When to Replace Your Safety Equipment

Replace Werner scaffolding every 8-12 years for heavy commercial use, 12-15 years for moderate residential use, and 15-20 years for occasional project work. Daily inspection shows metal fatigue, weld cracking, or platform warping requiring immediate replacement regardless of age.

You'll typically find aluminum components outlast steel in outdoor storage by 3-5 years. Here's what matters most: annual professional inspection costs $150-$300 but prevents equipment failure that could cost thousands in injury claims and project delays.

Visual Inspection Signs for Equipment Replacement

Check for hairline cracks around weld joints, especially on pump jack mounting points and platform connection areas. Metal fatigue appears as surface stress marks or slight bending under normal load conditions.

Platform surfaces showing wear patterns deeper than 1/8 inch need replacement within 6 months. The reality is worn platforms reduce weight capacity by 20-30% even when structural integrity appears intact.

Annual Maintenance Tasks and Replacement Schedules

Clean all components monthly during active use, removing concrete splatter and paint buildup that hides structural damage. Lubricate moving parts quarterly with marine-grade grease for corrosion protection.

Professional contractors replace safety nets every 3-4 years regardless of visible condition. Support braces need replacement every 5-7 years due to stress cycling from repeated assembly and disassembly.

Cost Analysis for Equipment Replacement vs Repair

Basic pump jack rebuilding costs $180-$220 including new hardware and professional inspection. Platform replacement runs $400-$800 depending on length, while complete system replacement averages $1,200-$3,500 for typical contractor setups.

Here's the thing about repair economics: components over 10 years old cost 60-80% of new price for professional rebuilding. Newer equipment under 5 years typically justifies repair unless structural damage exists.

Werner Scaffolding Protection Levels: Understanding Ratings and Standards

OSHA Standard 1926.452 requires Werner scaffolding support 4x intended load without failure, meaning 250-pound rated systems must handle 1,000 pounds during testing. Real-world protection levels depend on proper assembly, regular inspection, and component condition maintenance over equipment lifespan.

You'll typically find three protection categories: light-duty residential (250 pounds), medium-duty commercial (500 pounds), and heavy-duty industrial (750+ pounds). Werner pump jack systems meet medium-duty standards with proper accessory selection and professional installation.

OSHA Compliance Requirements for Different Work Types

Residential work under 10 feet height needs basic platform safety with personal fall arrest lanyards for workers. Commercial projects require full guardrail systems, toe boards, and certified anchor point connections for fall protection equipment.

The reality is insurance companies require OSHA-compliant installations for coverage validation. Non-compliant setups void liability protection and increase injury claim exposure significantly.

Weight Capacity Ratings and Real-World Applications

Werner 2-man stages handle 500 pounds distributed weight, including workers, tools, and materials. Concentrated loads over 150 pounds per square foot exceed design limits and require additional support bracing.

| Rating Level | Weight Capacity | Typical Use | Cost Impact |

|---|---|---|---|

| Light Duty | 250 lbs total | Paint, light repair | Base price |

| Medium Duty | 500 lbs total | Siding, windows | +$200-400 |

| Heavy Duty | 750+ lbs total | Masonry, roofing | +$600-1000 |

| Custom Engineered | Variable | Industrial applications | +$1500-3000 |

Professional vs DIY Installation Requirements

DIY installations work for basic residential projects under 16 feet with single-worker capacity. Professional setup costs $300-$500 but ensures proper load distribution and OSHA compliance for commercial work.

Here's what matters most: professional installation includes engineered calculations, proper foundation assessment, and certified inspection documentation required for insurance and regulatory compliance.

Common Werner Scaffolding Mistakes That Reduce Protection

#1 mistake: Exceeding weight capacity reduces protection by 40-60% and creates catastrophic failure risk within 2-3 uses. Overloading 500-pound rated platforms with 600+ pounds causes immediate structural stress and long-term component fatigue requiring complete system replacement.

You'll typically find contractors underestimate material weight, especially when storing full buckets, lumber stacks, or tool boxes on platforms. The reality is proper weight distribution prevents 85% of scaffolding failures and injury incidents.

Setup Errors That Compromise Structural Integrity

Improper pole spacing creates uneven load distribution and platform instability. Werner systems require precise measurements with poles plumb within 1/4 inch tolerance for safe operation.

Skipping support braces saves 10-15 minutes setup time but reduces platform stability by 50%. Rigid support braces cost $146 each but prevent lateral movement that causes worker falls and equipment damage.

Maintenance Neglect Leading to Equipment Failure

Storing equipment outdoors without covers accelerates corrosion and joint deterioration. Proper storage extends equipment life 3-5 years and maintains manufacturer warranty coverage for component replacement.

Here's the thing about lubrication: dry pump jack mechanisms increase operating force by 200% and cause premature wear. Monthly lubrication costs $15 in materials but prevents $400-800 replacement expenses.

Improper Accessory Selection and Installation

Using narrow end rails ($350) instead of wide end rails ($387) limits material storage and forces workers into unsafe positions. Wrong accessory selection increases fall risk and reduces work efficiency by 25-30%.

Safety net installation ($730) appears expensive but prevents fall injuries costing $50,000+ in medical expenses and project delays. Contractors often skip nets for cost savings but face liability exposure exceeding equipment investment by 50-100x.

Final Buying Checklist for Werner Scaffolding Systems

- Verify weight capacity meets total worker and material requirements

- Confirm platform length accommodates work area and material storage needs

- Select appropriate pole height with 3-foot safety margin above work level

- Include necessary support braces and safety accessories in initial purchase

- Plan for fall protection integration and OSHA compliance requirements

- Budget for annual inspection and maintenance costs throughout equipment lifespan

- Arrange proper storage facilities to protect investment and extend equipment life

- Consider professional installation for projects requiring engineered calculations and compliance documentation