Face Shields

Face Shields: Complete Protection Guide for Safety Equipment Selection

Face shields are transparent protective barriers that attach to headgear, providing full facial coverage against flying debris, chemical splashes, and airborne particles. These safety devices typically cost between $15-75 depending on features, with basic models suitable for light-duty work and premium versions offering specialized protection. Professional users rely on face shields in healthcare, manufacturing, and construction environments where eye protection alone proves insufficient. All Safety serves as a trusted provider of comprehensive face shield solutions for Canadian workplaces requiring reliable facial protection equipment.

What Are Face Shields and How Do They Work?

Face shields consist of a clear visor made from polycarbonate or acetate materials, mounted on adjustable headgear that positions the barrier approximately 2-4 inches from your face. The transparent shield creates a protective zone covering your entire face from forehead to chin, deflecting hazardous materials while maintaining clear visibility. Unlike safety glasses that protect only the eye area, face shields provide comprehensive coverage including the nose, mouth, and cheek areas. Modern designs incorporate anti-fog coatings and ventilation systems to prevent moisture buildup during extended wear.

Key Benefits of Using Face Shields for Workplace Safety

The primary benefits include complete facial protection against splashes, impact resistance from flying objects, and optical clarity for precise work tasks. Face shields enable users to maintain normal vision while working in hazardous environments, unlike enclosed protective equipment that restricts visibility. These devices integrate easily with other safety equipment including hard hats for complete head protection and respiratory protection systems. Workers experience reduced eye strain compared to safety glasses, especially during extended tasks requiring visual precision.

Understanding Face Shield Limitations and Proper Usage

Face shields cannot protect against fine dust particles or chemical vapors that may flow around the edges, requiring additional respiratory protection in contaminated environments. The open design allows airborne particles to potentially reach the breathing zone from below or sides. Users must combine face shields with appropriate eye protection equipment when impact hazards exceed the shield's protection level. All Safety emphasizes that face shields work best as part of comprehensive personal protective equipment systems rather than standalone protection.

Who Should Use Face Shields in Professional Settings?

Healthcare workers handling infectious materials benefit from face shields' splash protection during medical procedures and patient care activities. Manufacturing personnel operating grinders, lathes, or cutting equipment require face shields to guard against metal shavings and debris. Chemical plant workers use specialized face shields when handling corrosive substances that could cause severe facial burns. Construction workers benefit from face shield protection during demolition, grinding, and overhead work where debris commonly falls.

Industry-Specific Face Shield Applications

- Medical facilities require shields with anti-fog properties for extended surgical procedures and patient examination tasks

- Welding operations need specialized welding face shields with proper filtration for arc protection

- Laboratories use chemical-resistant shields during experiments involving hazardous substances and reactive materials

- Food processing plants utilize face shields to maintain hygiene while protecting against splashes and cleaning chemicals

- Woodworking shops rely on impact-resistant shields to deflect wood chips and sawdust particles

When to Use Face Shields: Timing and Situations

Use face shields whenever work involves potential splash hazards, flying particles, or when other workers operate equipment that creates debris in your vicinity. Emergency response situations often require immediate face shield deployment, particularly when dealing with unknown chemical substances or during rescue operations. Maintenance tasks involving overhead work, pressure washing, or chemical cleaning typically necessitate face shield protection. All Safety recommends implementing face shields during any activity where facial injury risk exists, even when other safety measures are present.

Face Shield Costs and Budget Considerations

Basic disposable face shields typically cost $2-8 each, suitable for single-use applications in medical or food service environments. Reusable models with adjustable headgear range from $15-40, offering durability for regular industrial use. Premium face shields with specialized features like anti-fog coatings, UV protection, or chemical resistance cost $50-75, justified for demanding professional applications. Replacement visors typically cost 30-50% of the complete unit price, making maintenance affordable for long-term use.

Total Cost of Ownership Factors

Consider replacement visor costs, cleaning supplies, and storage requirements when budgeting for face shield programs. Organizations typically spend $25-60 per worker annually on face shield maintenance and replacement, depending on usage intensity and environment severity. Bulk purchasing often reduces unit costs by 20-30% for organizations outfitting multiple workers. Factor in training costs and compliance requirements when calculating complete program expenses.

Essential Features to Look for When Selecting Face Shields

Optical clarity ratings ensure clear vision without distortion, with Class 1 optical quality recommended for precision work requiring visual accuracy. Anti-fog coatings prevent moisture buildup during temperature changes and physical exertion, maintaining visibility throughout work shifts. Impact resistance ratings indicate protection levels, with face shields typically meeting ANSI Z87.1+ standards for high-impact applications. Adjustable headgear ensures proper fit across different head sizes and accommodates various hairstyles and protective headwear.

Face Shield Materials and Construction Quality

Polycarbonate visors offer excellent impact resistance and optical clarity, suitable for most industrial applications requiring durability and clear vision. Acetate materials provide superior chemical resistance for environments involving acids, bases, or organic solvents. Shield thickness typically ranges from 0.04-0.15 inches, with thicker materials offering enhanced impact protection but potentially reduced optical quality. Frame materials include lightweight plastics for comfort during extended wear and metal options for demanding industrial environments.

Proper Maintenance and Care for Face Shield Equipment

Clean face shields daily using mild soap solutions and soft cloths to maintain optical clarity and remove contamination buildup. Avoid abrasive cleaners or rough materials that could scratch the visor surface and compromise visibility or protection. Store shields in clean, dry locations away from direct sunlight to prevent material degradation and discoloration. Inspect shields before each use for cracks, scratches, or loose components that could compromise protection effectiveness.

Replacement and Lifecycle Management

Replace visors immediately when scratches affect visibility or when cracks appear anywhere on the surface, as these defects compromise protection integrity. Most industrial face shields require visor replacement every 3-6 months under normal use conditions, with more frequent changes needed in harsh environments. All Safety recommends maintaining spare visors to ensure continuous protection when primary equipment requires replacement or repair.

Safety Standards and Compliance Requirements

Face shields must meet ANSI Z87.1 standards for impact resistance and optical quality in industrial applications throughout North America. CSA Z94.3 standards apply to Canadian workplaces, ensuring compatibility with other protective equipment and adequate protection levels. Look for proper marking and certification labels on both the visor and frame components to verify compliance. Regular inspection and documentation help maintain compliance with workplace safety regulations and insurance requirements.

Troubleshooting Common Face Shield Problems

Address fogging issues through proper cleaning, anti-fog treatments, or improved ventilation around the work area to maintain clear visibility. Adjust headgear tension and positioning if shields slip during use, ensuring stable protection without excessive pressure causing discomfort. Replace worn adjustment mechanisms that no longer maintain proper positioning, as loose shields provide inadequate protection. Monitor for material degradation including yellowing, crazing, or brittleness that indicates replacement necessity.

Face Shield Selection Quick Reference Guide

- Verify ANSI Z87.1+ compliance for impact protection and optical quality standards

- Check compatibility with existing hard hat mounting systems and accessories

- Measure coverage area to ensure protection extends below chin and around face sides

- Test optical clarity under work lighting conditions to confirm visibility requirements

- Calculate total program costs including replacement parts, cleaning supplies, and training expenses

- Evaluate material chemical resistance against specific workplace hazards and substances

- Inspect adjustment mechanisms for smooth operation and secure positioning capabilities

- Review manufacturer warranty terms and replacement part availability for long-term support

Professional Installation and Training Services

Proper implementation requires worker training on correct usage, maintenance procedures, and limitation understanding to ensure effective protection. All Safety provides comprehensive training programs covering face shield selection, fitting, and integration with other safety equipment systems. Organizations benefit from professional assessment of workplace hazards to determine appropriate face shield specifications and usage protocols. Consider partnering with safety equipment providers offering ongoing support and compliance assistance for sustained protection programs.

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

QUAD 500 Faceshield Clear Antifog PC-Shd 5 FLIP | Jackson Safety

Jackson Safety

$132.73Description The QUAD 500 offers an unparalleled range of face and eye protection solutions for almost every application including grinding cutting oxy/acetylene plasma cutting and brazing. It offers exceptional panoramic views with virtually no...$132.73 -

QUAD 500 Faceshield Clear Antifog PC-Shd 8 FLIP | Jackson Safety

Jackson Safety

$136.12Description The QUAD 500 offers an unparalleled range of face and eye protection solutions for almost every application including grinding cutting oxy/acetylene plasma cutting and brazing. It offers exceptional panoramic views with virtually no...$136.12 -

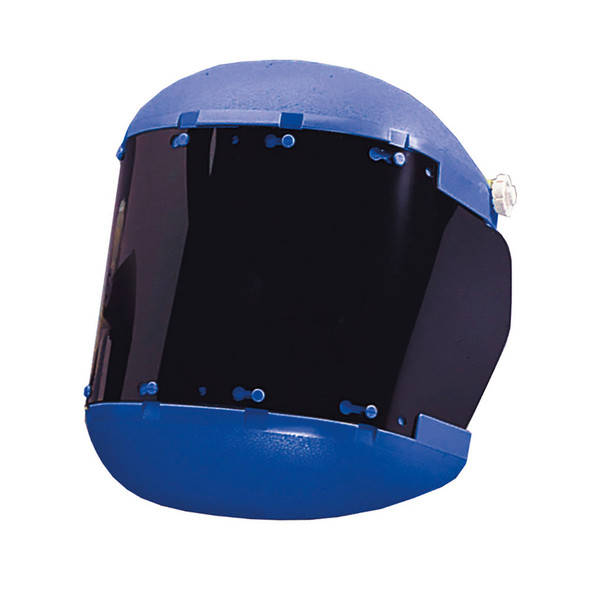

Sellstrom Dual Crown Face Shield with Ratcheting Headgear - Shade 5 IR -Uncoated

Sellstrom

$147.04Description Adjustable: These assembled face shields come with a ratchet suspension headgear and a twist knob allowing easy customization of height and fit; The convenient system gives you flexibility to handle various types of grinding brazing &...$147.04 -

37. Dynamic Deluxe Kit | Dynamic

Dynamic Safety

$178.11Features (1) HP142R15 Class 2 Red Safety Hat (1) EPB103 Faceshield Bracket (1) EPWM815 Metal Forestry Screen Visor (1) NP118 "B52" EarMuff$178.11 -

High Performance Safety Headgear | 12/Pack | Dynamic

Dynamic Safety

$325.30Manufacturer: DSI Safety Material: HDPE Brand: DSI Safety Accepts a wide range of faceshield styles. Large sparkguard provides excellent protection. Cross strap adjusts to allow an exceptional fit. Full floating mount sparkguard provides comfortable wear...$325.30 -

MFS-320 Reusable Splash Face Shield 24/Pack | Jackson Safety

Jackson Safety

$333.07Description Uses: Ideal for splash protection against liquids and body fluids for health care workers first responders and in food processing applications Features: Baseball cap style pinlock head strap ensures quick and easy adjustments Recyclable:...$333.07 -

High Performance Crown Faceshield Headgear | 12/Pack | Dynamic

Dynamic Safety

$342.797? crown face shield, Headgear with ratchet suspension head band- heavy dutymade out of NORYL.$342.79