Jackson Safety

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

Wilson 15-oz Carbonized Acrylic Felt Blanket - 4' x 6'*

Jackson Safety

$97.65Wilson* 15-oz Carbonized Acrylic Felt Blanket - 4' x 6' | Jackson SafetyANSI/ FM-4950 certified for use in horizontal applications (1.4.1) with severe exposures such as that resulting from molten...$97.65 -

Wilson Green Canvas Welding Curtain - 5' x 8'*

Jackson Safety

$97.33Wilson* Green Canvas Welding Curtain - 5' x 8' | Jackson SafetyGreen 12 oz. cotton duck materialFlame, water and mildew resistantGrommeted and ready-to-hang (tubing or framing not included)$97.33 -

Wilson Weld-O-Glass 15-oz Fiberglass Blanket, Acrylic Coated - 10' x 10'*

Jackson Safety

$134.33Description Wilson high-temperature fabrics are used to protect equipment and personnel near hazardous operations such as welding flame-cutting and grinding. These fabrics can be used as blankets...$134.33 -

Wilson Weld-O-Glass 15-oz Fiberglass Blanket, Acrylic Coated - 5' x 5'*

Jackson Safety

$41.71Wilson* Weld-O-Glass 15-oz Fiberglass Blanket, Acrylic Coated - 5' x 5' | Jackson SafetyANSI/ FM-4950 certified for use in vertical applications (1.4.3) with light-moderate exposures resulting from...$41.71 -

Wilson Weld-O-Glass 24-oz Fiberglass Black Welding Blanket - Vermiculite Coated - 3' x 3'*

Jackson Safety

$29.90Wilson* Weld-O-Glass 24 oz Fiberglass Black Welding Blanket - Vermiculite Coated - 3' x 3' | Jackson SafetyPrevents sparks from escaping a confined areaGrommets on four sidesSeries: Weld-O-Glass...$29.90 -

Wilson Weld-O-Glass 24-oz Fiberglass Blanket, Vermiculite Coated - 5' x 5'*

Jackson Safety

$63.95Wilson* Weld-O-Glass 24-oz Fiberglass Blanket, Vermiculite Coated - 5' x 5' | Jackson SafetyANSI/ FM-4950 certified for use in vertical applications (1.4.3) with lightmoderate exposures resulting...$63.95 -

Wilson Weld-O-Glass 24-oz Fiberglass Blanket, Vermiculite Coated*

Jackson Safety

$47.54 - $59.76Wilson* Weld-O-Glass 24-oz Fiberglass Blanket, Vermiculite Coated | Jackson SafetyANSI/ FM-4950 certified for use in vertical applications (1.4.3) with lightmoderate exposures resulting from...$47.54 - $59.76 -

Wilson Weld-O-Glass 36-oz Silica Blanket, Uncoated - 5' x 10'*

Jackson Safety

$244.49Description Sellstrom® molded clear face shield replacement windows for Jackson and Sellstrom universal pin mount headgear. Use With: Replacement flip front visor for Sellstrom DP4 safety face...$244.49 -

Wilson Welding Blanket | Surewerx

Jackson Safety

$41.36 - $309.17Description Jackson® Safety Wilson® Silicone Coated Fiberglass Welding Blankets are used to protect equipment and personnel near hazardous operations such as welding flame-cutting and...$41.36 - $309.17 -

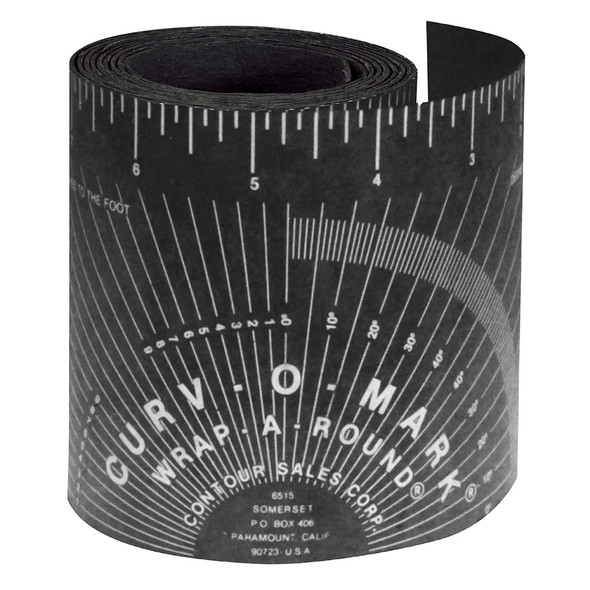

Wrap-A-Round | Jackson Safety

Jackson Safety

$32.98 - $90.61Description Jackson® Curve-O-Mark® Wrap-A-Round Tools are used by pipe fitters and welders alike this is an economical precision tool used to mark straight lines around pipes or to mark a...$32.98 - $90.61 -

WS Series IRUV Shade 5 Cutting Goggle 2 X 4.25 Flip

Jackson Safety

$21.46Descrpition These goggles provide a comfortable yet snug seal to keep your eyes safe while welding and cutting and the indirect vents provide superior ventilation and fog free results. Includes a...$21.46 -

WS Series IRUV Shade 5 Cutting Goggle 50 MM Eye Cup

Jackson Safety

$12.83Descrpition These eye cup goggles provide a comfortable yet snug seal for optimal protection and the lightweight design is both sturdy and durable. 50mm round Shade 5 IRUV lenses in a retro eye-cup...$12.83 -

XS2-500 Type 2 Safety Helmet - Non-Vented | Jackson Safety

Jackson Safety

$139.91Built to fit workers who demand more than just a climbing helmet or hard hat the XS2-500 combines advanced protection with superior comfort. Constructed from premium materials this helmet delivers...$139.91 -

XS2-500 Type 2 Safety Helmet - Vented | Jackson Safety

Jackson Safety

$139.91Built to fit workers who demand more than just a climbing helmet or hard hat the XS2-500V combines cutting-edge protection with superior comfort. Constructed from premium materials this helmet...$139.91

Jackson Safety Equipment: Complete Welding and Fabrication Product Range

Jackson Safety specializes in professional welding safety equipment and precision fabrication tools designed for metalworking industries. The brand offers comprehensive solutions including welding helmets, protective gear, and the renowned Curv-O-Mark line of pipe marking and alignment tools.

Jackson Safety serves welders, fabricators, and metalworking professionals who require reliable protection and precision tools for industrial applications. Their product line encompasses both personal protective equipment and specialized measuring instruments essential for quality welding and fabrication work.

Key Takeaways About Jackson Safety Equipment

- Jackson Safety provides specialized welding protection equipment for professional metalworking applications and industrial fabrication environments

- Jackson Safety manufactures precision Curv-O-Mark tools that enable accurate pipe marking, alignment, and measurement for welding projects

- Jackson Safety welding helmets offer reliable head protection with advanced features designed specifically for professional welding operations

- Jackson Safety protective blankets use durable materials to shield work areas from welding sparks and heat damage

- Jackson Safety serves fabricators, pipe fitters, and welding professionals across construction, manufacturing, and industrial maintenance sectors

- Jackson Safety equipment meets industry safety standards while providing the precision and durability required for professional welding work

- Jackson Safety combines personal protection with specialized tools to address both safety and accuracy needs in metalworking operations

Jackson Safety Products for Different Industries and Applications

Jackson Safety serves multiple industries where welding and fabrication are essential operations. The brand's equipment is widely used in construction, manufacturing, oil and gas, shipbuilding, and general metalworking applications.

Primary Industries Using Jackson Safety Equipment

Construction companies rely on Jackson Safety welding helmets and protective gear for structural welding projects. Manufacturing facilities use their precision tools for consistent fabrication work, while maintenance departments depend on their durable equipment for ongoing repairs and modifications.

Specialized Applications for Jackson Safety Tools

Pipe fitting operations benefit significantly from Curv-O-Mark alignment tools, which ensure precise measurements and proper fitting procedures. Fabrication shops use Jackson Safety's comprehensive tool line for both protection and accuracy in complex metalworking projects.

Industry-Specific Applications List for Jackson Safety:- Construction Welders: Perform structural welding on building sites, face exposure to sparks and UV radiation, use Jackson Safety welding helmets for comprehensive head protection, benefit from adjustable features for extended wear comfort

- Pipe Fabrication Shops: Create precise pipe assemblies and fittings, require exact measurements and alignments, use Curv-O-Mark tools for accurate marking and positioning, benefit from professional-grade precision instruments

- Manufacturing Facilities: Conduct repetitive welding operations on production lines, need consistent protection and tool performance, use Jackson Safety equipment for reliable daily operations, benefit from durable construction for extended use

- Maintenance Departments: Perform repair welding in industrial environments, work with various materials and configurations, use versatile Jackson Safety tools for different applications, benefit from comprehensive equipment solutions

- Shipbuilding Operations: Execute complex welding in confined spaces, require specialized protection and precision tools, use Jackson Safety equipment for marine-grade applications, benefit from equipment designed for challenging environments

- Oil and Gas Contractors: Work on pipeline and facility construction projects, need equipment that performs in harsh conditions, use Jackson Safety tools for critical infrastructure work, benefit from reliable equipment for high-stakes applications

How to Select Jackson Safety Products: Professional Buying Guide

Selecting appropriate Jackson Safety equipment requires evaluating your specific welding applications, work environment conditions, and precision requirements. Consider the types of materials you'll be working with and the level of protection needed for your operations.

Key Factors for Jackson Safety Product Selection

Evaluate your welding processes to determine the appropriate helmet features and protective equipment specifications. Consider the frequency of use, as professional-grade Jackson Safety equipment is designed for demanding daily applications rather than occasional use.

Professional Selection Process for Jackson Safety Equipment

- Assess your primary welding processes and material types for proper equipment matching

- Determine work environment conditions including space constraints and hazard levels

- Evaluate precision requirements for measuring and alignment tool specifications

- Consider frequency of use to select appropriate durability and performance levels

- Review compatibility with existing equipment and workflow integration needs

- Compare Jackson Safety features against specific job requirements and preferences

- Verify compliance with relevant safety standards for your industry applications

Jackson Safety Quality Evaluation Criteria

Jackson Safety products are distinguished by their construction quality and precision engineering. Their Curv-O-Mark tools feature accurate measurement capabilities, while their protective equipment offers reliable performance under demanding conditions.

Jackson Safety Product Features and Technology Explained

Jackson Safety equipment incorporates professional-grade materials and precision engineering to meet the demands of industrial welding applications. Their welding helmets feature advanced protection systems, while Curv-O-Mark tools provide accurate measurement and alignment capabilities.

Welding Protection Technology in Jackson Safety Equipment

Jackson Safety welding helmets utilize durable construction materials designed to withstand industrial use. The helmets feature adjustable systems for comfortable extended wear and reliable protection against welding hazards including UV radiation and flying sparks.

Curv-O-Mark Precision Tool Technology

The Curv-O-Mark line represents Jackson Safety's commitment to precision fabrication tools. These instruments provide accurate pipe marking, centering, and alignment capabilities essential for professional welding and fitting operations.

Professional Metalworking Applications for Jackson Safety Equipment

Professional metalworkers depend on Jackson Safety equipment for both protection and precision in their daily operations. The brand's comprehensive approach addresses the dual needs of safety compliance and work quality in demanding industrial environments.

Daily Operations with Jackson Safety Tools

Welders use Jackson Safety helmets throughout their shifts, relying on consistent protection and comfort features. Fabricators integrate Curv-O-Mark tools into their measurement and marking processes, ensuring accuracy in complex projects that require precise specifications.

Workplace Safety Integration

Jackson Safety equipment helps facilities maintain safety compliance while supporting productive operations. The equipment is designed to integrate smoothly into existing workflows without compromising efficiency or adding unnecessary complexity to standard procedures.

Jackson Safety Product Maintenance and Longevity Guide

Jackson Safety equipment requires regular maintenance to ensure optimal performance and extended service life. Proper care includes cleaning protective equipment after use and storing precision tools in appropriate conditions to maintain their accuracy.

Maintaining Jackson Safety Welding Equipment

Welding helmets should be inspected regularly for damage to protective lenses and adjustment mechanisms. Clean equipment after each use to remove welding residue and check that all protective features are functioning properly for continued safety.

Caring for Curv-O-Mark Precision Tools

Precision tools require careful handling and storage to maintain their accuracy. Keep tools clean and properly calibrated, and store them in protective cases when not in use to prevent damage that could affect measurement precision.

Replacement Indicators for Jackson Safety Equipment

Replace welding helmets when protective lenses show significant damage or when adjustment mechanisms no longer function properly. Precision tools should be replaced when they no longer provide accurate measurements or show signs of mechanical wear that affects their performance.

Jackson Safety Quality Standards and Certifications

Jackson Safety products meet relevant industry safety standards for welding protection and precision tool manufacturing. The brand maintains quality control processes to ensure consistent performance across their product lines.

Safety Compliance for Jackson Safety Equipment

Jackson Safety welding protection equipment meets industry safety standards for personal protective equipment used in welding applications. Their products are designed to provide reliable protection against common welding hazards when used according to specifications.

Precision Tool Quality Standards

Curv-O-Mark tools are manufactured to precision standards appropriate for professional fabrication applications. The tools undergo quality control processes to ensure they meet accuracy requirements for industrial use.

Jackson Safety Pricing Strategy: Value and Investment Analysis

Jackson Safety positions itself as a professional-grade brand offering quality equipment for serious welding and fabrication applications. The pricing reflects the specialized nature of their products and their target market of professional users.

Investment Considerations for Jackson Safety Equipment

Professional welders and fabricators typically view Jackson Safety equipment as a long-term investment in both safety and work quality. The equipment is designed for frequent use and demanding applications, making it suitable for operations where reliability is essential.

Total Cost Analysis for Jackson Safety Products

Consider the total cost of ownership including initial purchase price, maintenance requirements, and replacement schedules. Jackson Safety equipment generally provides good value for professional applications where quality and reliability are priority considerations.

Comparing Jackson Safety Value Proposition

| Factor | Jackson Safety Advantage | Consideration |

|---|---|---|

| Durability | Professional-grade construction | Higher initial investment |

| Precision | Curv-O-Mark accuracy | Specialized tool requirements |

| Application Range | Comprehensive welding solutions | Focus on specific industries |

Jackson Safety Product Selection Checklist

- Verify equipment meets your specific welding process protection requirements

- Check tool precision specifications match your fabrication accuracy needs

- Evaluate compatibility with existing welding equipment and workflow processes

- Compare features against your frequency of use and durability requirements

- Assess total cost including maintenance and replacement considerations over time

- Review user feedback for similar applications in your industry sector

- Confirm availability of replacement parts and accessories for long-term support

- Consider training requirements for proper use of specialized Curv-O-Mark tools

Jackson Safety serves professional welders and fabricators who require reliable protection equipment and precision tools for demanding industrial applications. The brand's focus on quality construction and specialized features makes it particularly suitable for operations where both safety and work precision are essential requirements. When selecting Jackson Safety equipment, consider your specific welding processes, work environment conditions, and the level of precision required for your applications. Information current as of June 25, 2025.