Description

Key Features:

10-Foot Rail: The primary component of this system is a 10-foot rail which is used as a horizontal safety bar or attachment point. This rail provides stability and can be used to mount other fall protection devices like harnesses lifelines or winches.

Two Anchor Points: The two anchor points are essential for securing ropes safety lines or other equipment that ensures workers are tethered and protected from falls. Anchor points can be attached to the rail and then to the worker’s safety harness or other devices to prevent them from falling or to allow for safe lowering and hoisting in rescue scenarios.

Heavy-Duty Construction: As with most Tuff Built products the rail and anchor points are made from industrial-grade materials like steel or aluminum designed for durability long-term use and to support heavy loads safely. This ensures reliability and stability even in harsh work environments.

Versatile Application: This system is suitable for use in various environments particularly those where safety is a concern. It can be used in confined spaces like manholes tanks and pits or on construction sites and in industrial plants. The rail helps provide a horizontal anchor for safety lines or lifelines and works effectively when installed across gaps or high areas.

Portable and Easy to Set Up: The rail and anchor points are designed to be portable making them easy to transport and set up quickly. This is important for emergency scenarios where quick access and rapid deployment are essential.

Common Uses:

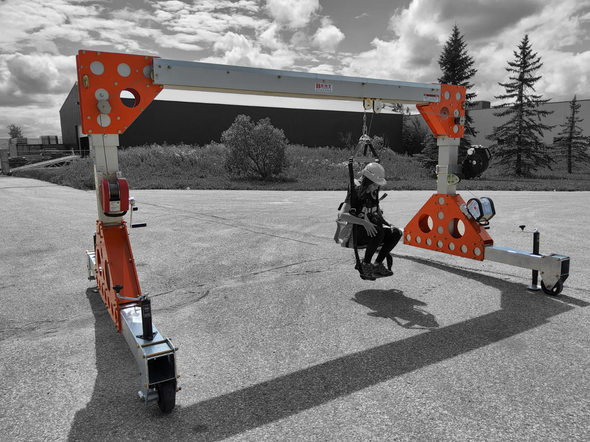

Confined Space Entry: The rail and anchor points can be used to help workers safely enter and exit confined spaces. The system provides a point for securing the worker’s harness ensuring they can be safely raised or lowered into a confined space.

Fall Protection System: The system can be used as part of a larger fall protection plan on construction sites factories or industrial facilities. The rail serves as a reliable horizontal anchor for lifelines or personal fall arrest systems.

Rescue Operations: In emergency rescue situations the rail and anchor points provide a secure system for retrieving workers from hazardous environments. The anchor points may be used for ropes or hoisting devices to safely remove an individual from a dangerous area.

Specifications:

Material: Likely constructed from high-strength steel or aluminum ensuring it is both lightweight and durable enough to handle heavy loads.

Length: The 10-foot rail provides adequate coverage for horizontal fall protection and may be used in various configurations depending on the work environment.

Anchor Points: The two anchor points are strategically placed for optimal use ensuring that there are multiple options for securing a worker’s safety equipment.

Load Capacity: While the exact load capacity can vary depending on the rail’s design and installation it is likely built to comply with safety standards that ensure it can safely support the weight of personnel in case of a fall.

Adjustability: The rail may be adjustable to accommodate different installation heights or lengths depending on the needs of the worksite.

Safety Considerations:

Proper Installation: Ensure that the rail and anchor points are installed on solid stable structures capable of withstanding the forces involved in a fall. This is especially important for confined spaces or rescue situations where lives are at risk.

Inspection and Maintenance: As with any fall protection equipment regular inspection and maintenance are necessary to ensure the system is in good working condition. The anchor points should be checked for stability corrosion or wear and the rail should be securely mounted to prevent accidents.

Training: Workers should be properly trained on how to use the rail system including how to attach and detach from anchor points and how to ensure the system is set up correctly for safe use.

Compliance:

This system likely meets or exceeds relevant OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) standards for fall protection and safety equipment. It's important to verify compliance based on the specific worksite requirements.

![Rail 10' w/Anchar Points [2] | Tuff Built | All Safety Rail 10' w/Anchar Points [2] | Tuff Built | All Safety](https://cdn11.bigcommerce.com/s-oizklbqtoh/images/stencil/608x608/products/11024/37760/20014__51648.1767671289.jpg?c=1)

![Davits [2] w/Anchar Points [2] | Tuff Built | All Safety Davits [2] w/Anchar Points [2] | Tuff Built | All Safety](https://cdn11.bigcommerce.com/s-oizklbqtoh/images/stencil/590x590/products/11017/37759/20014__17877.1767671211.jpg?c=1)

![Simplicity Exosphere Anchor System [24'] w/Forklift Base | Tuff Built | All Safety Simplicity Exosphere Anchor System [24'] w/Forklift Base | Tuff Built | All Safety](https://cdn11.bigcommerce.com/s-oizklbqtoh/images/stencil/590x590/products/11054/37831/71212__45974.1767683210.jpg?c=1)

![Simplicity Exosphere Anchor System [24'] w/Forklift Base | Tuff Built | All Safety Simplicity Exosphere Anchor System [24'] w/Forklift Base | Tuff Built | All Safety](https://cdn11.bigcommerce.com/s-oizklbqtoh/images/stencil/590x590/products/11054/37833/71212__01773.1767683213.png?c=1)