Pipe Measuring Tools

What Are Pipe Measuring Tools: Complete Guide

Pipe measuring tools are specialized instruments designed to accurately measure, mark, and align pipes during fabrication, welding, and installation processes. These precision tools help pipefitters, welders, and contractors ensure proper pipe alignment, calculate angles, find center points, and mark cutting lines on cylindrical surfaces. Professional pipe measuring tools include wrap-around markers, center finders, angle protractors, flange aligners, and radius markers that work with pipes ranging from small diameter tubing to large industrial piping systems.

Accurate pipe measurement directly impacts the quality and safety of piping installations across industries. When workers use proper measuring tools, they reduce material waste from incorrect cuts, minimize rework time, and ensure connections meet engineering specifications. Pipe measuring tools eliminate guesswork in complex fitting calculations, helping teams maintain consistent quality standards throughout fabrication and installation projects.

Industrial facilities, construction sites, and fabrication shops rely on these tools for daily operations. Professionals working with welding protection equipment and welding supplies understand that precise measurements prevent costly errors and safety hazards. Whether you're aligning flanges on a pressure vessel, marking cut lines on structural pipe, or calculating offsets for complex piping runs, having the right measuring tools ensures projects meet specifications the first time.

Key Takeaways About Pipe Measuring Tools for Industrial Applications

- Pipe measuring tools provide accurate measurements on cylindrical surfaces where standard measuring devices fail to deliver consistent results

- Professional-grade tools handle pipe diameters from 1 inch to 60 inches depending on the specific instrument and application requirements

- Magnetic mounting features allow hands-free operation, enabling workers to mark and measure simultaneously while maintaining proper safety positioning

- Wrap-around markers eliminate the need for complex calculations when marking straight lines around pipe circumferences for cutting operations

- Center-finding tools quickly locate exact pipe centers for drilling, welding, and alignment tasks without time-consuming trial and error methods

- Angle measurement tools help fabricators achieve precise miter cuts and fitting angles required for complex piping configurations and connections

- Durable construction withstands harsh industrial environments including exposure to sparks, impacts, and temperature variations common in fabrication shops

Where to Use Pipe Measuring Tools in Your Business

Pipe measuring tools serve essential functions in fabrication shops where workers cut, fit, and weld pipe assemblies before installation. Fabricators use wrap-around markers to create accurate cut lines around pipe circumferences, ensuring square cuts that fit properly during assembly. Center-finding tools help locate exact drilling points for branch connections, support brackets, and instrumentation ports. These tools reduce setup time and improve accuracy compared to traditional measuring methods that require multiple measurements and calculations.

Construction sites benefit from portable pipe measuring tools during field installations and modifications. Contractors working on plumbing systems, HVAC installations, and process piping use these tools to verify field measurements, check alignment before welding, and mark pipes for on-site cutting. The ability to quickly measure and mark pipes in awkward positions or confined spaces makes these tools valuable for both new construction and renovation projects. Workers can maintain accuracy even when working from ladders, scaffolding, or in mechanical rooms with limited space.

Industrial maintenance teams use pipe measuring tools during plant turnarounds, equipment repairs, and system upgrades. When replacing damaged pipe sections or modifying existing systems, accurate measurements ensure new components fit existing connections without requiring extensive field modifications. Maintenance workers also use these tools to document existing pipe configurations, create accurate sketches for ordering materials, and verify that replacement parts match specifications before removing old components.

Do businesses really need specialized pipe measuring tools? Operations that occasionally work with pipe can manage with basic measuring devices, though work takes longer and accuracy suffers. Companies that regularly fabricate or install piping systems benefit significantly from proper measuring tools through reduced rework, faster project completion, and fewer material costs from incorrect cuts. The investment typically pays for itself within the first few projects through time savings and reduced waste.

How to Choose Pipe Measuring Tools: Buying Guide

Selecting appropriate pipe measuring tools starts with understanding your typical pipe size range. Tools designed for small diameter pipe (1-12 inches) differ significantly from those handling large diameter pipe (12-60 inches). Evaluate the pipe sizes you work with most frequently, and choose tools that cover your common range with some capacity for occasional larger or smaller projects. Multi-purpose tools that adjust across various diameters provide versatility for shops handling diverse projects.

- Assess typical pipe diameter range you work with most frequently in daily operations

- Determine required measurement types: angles, centers, circumference lines, or flange alignment

- Evaluate magnetic versus non-magnetic mounting based on pipe material and positioning needs

- Consider tool durability requirements for your work environment and handling conditions

- Check compatibility with marking instruments you currently use in your operation

- Compare accuracy specifications to ensure tools meet your project tolerance requirements

- Review ergonomic features for tools used frequently throughout extended work shifts

Material construction quality affects tool longevity and measurement accuracy over time. Professional-grade measuring tools feature aluminum or steel construction that withstands drops, impacts, and exposure to welding sparks without losing calibration. Check for clear, permanently marked measurement scales that won't wear off with regular handling and exposure to solvents or cutting fluids. Tools with replaceable components like marking tips or alignment pins offer better long-term value than fully disposable units.

What separates budget pipe measuring tools from professional models? Entry-level tools often use plastic components that wear quickly, have less precise tolerances, and offer limited size ranges. Professional tools provide consistent accuracy across their full measurement range, maintain calibration through heavy use, and include features like magnetic mounts or multiple marking positions that increase productivity. For businesses where accurate pipe work affects safety or system performance, professional-grade tools deliver reliability worth the additional investment.

Key Features of Pipe Measuring Tools Explained

Wrap-around marking capability allows workers to create perfectly straight lines around pipe circumferences without complex calculations or multiple measurements. These tools feature flexible rulers or rigid frames that conform to pipe diameter, with slots or guides for marking instruments. The wrap-around design ensures lines remain parallel to pipe ends, critical for achieving square cuts that fit properly during assembly. This feature eliminates the common problem of "spiraling" that occurs when trying to mark straight lines freehand on cylindrical surfaces.

Magnetic mounting systems free both hands for marking and measuring operations, improving safety and accuracy. Tools equipped with strong magnets attach securely to ferrous pipe materials, maintaining position even when workers need to reposition themselves or adjust equipment. This hands-free capability proves especially valuable when working on elevated platforms requiring fall protection equipment or in confined spaces where maintaining balance takes priority. Non-magnetic versions use mechanical clamps or adjustable legs for use with stainless steel, aluminum, or plastic pipe systems.

Angle measurement capabilities help fabricators calculate and mark precise miter cuts for pipe fittings and connections. Professional angle-finding tools include protractors, level indicators, and alignment guides that show exact cutting angles required for various fitting configurations. These features reduce the trial-and-error approach to fitting complex piping arrangements, helping teams achieve proper alignment on the first attempt. Accurate angle measurements become particularly important in pressure systems where misalignment creates stress concentration points that can lead to failures.

Center-finding mechanisms quickly locate the exact center point of pipe cross-sections for drilling, welding, or mounting operations. These tools use adjustable arms or triangulation methods to identify center regardless of pipe diameter variation or out-of-round conditions. Finding centers accurately matters when installing branch connections, mounting pipe supports, or positioning instrumentation taps where precise location affects system function. Manual center-finding methods require multiple measurements and calculations that consume time and introduce potential errors.

Professional Pipe Layout Tools Uses

Professional pipefitters rely on advanced measuring tools for complex layout work involving multiple pipe runs, fitting assemblies, and precise spacing requirements. When fabricating pipe racks, support systems, or process equipment, professionals use combination measuring tools that provide multiple reference points simultaneously. These tools help maintain consistent spacing between parallel pipe runs, ensure proper elevation alignment, and verify that branch connections orient correctly relative to main pipe runs. Professional layout work demands accuracy that compounds throughout large assemblies, making reliable measuring tools essential for maintaining specifications.

Industrial contractors working on high-pressure systems use specialized flange alignment tools that verify proper mating surface alignment before bolting connections. These precision instruments measure flange face parallelism, gap spacing, and bolt hole alignment to ensure connections meet code requirements for pressure-retaining systems. Proper flange alignment prevents gasket crushing, uneven loading, and potential leak paths that compromise system integrity. Professionals understand that spending extra time verifying alignment prevents costly leaks and forced outages that exceed the time investment many times over.

Welding professionals use pipe measuring tools to verify fit-up conditions before striking arcs, ensuring proper gap spacing, alignment, and joint preparation. Tools designed for welding applications often include features for checking root opening dimensions, land width on beveled edges, and alignment offset between mating pipe sections. These measurements directly affect weld quality, penetration, and structural integrity of completed joints. Professional welders working with welding helmets and protective equipment depend on accurate pre-weld measurements to produce code-quality joints consistently.

Fabrication shops handling large-diameter pipe benefit from specialized measuring tools designed for pipes exceeding 24 inches in diameter. These heavy-duty tools feature extended measurement ranges, reinforced construction, and mounting systems capable of securing to large pipe surfaces. Large pipe projects in power generation, petrochemical processing, and water treatment require the same measurement accuracy as smaller pipe but present unique challenges due to weight, handling limitations, and the compounding effect of small errors across large circumferences.

Industry-Specific Applications for Pipe Measuring Tools

- Oil and Gas: Pipeline construction teams face challenges measuring and aligning large-diameter transmission pipe in field conditions, using specialized tools to verify fit-up before welding critical mainline connections that operate at high pressures and must meet stringent inspection requirements

- Power Generation: Boiler and steam system installers work with high-temperature piping requiring precise alignment to prevent thermal expansion problems, relying on accurate measuring tools to establish proper support locations and expansion loop dimensions that accommodate thermal movement

- Chemical Processing: Process piping fabricators need exact measurements for systems handling corrosive or hazardous materials, using specialized tools to ensure proper drainage slopes, verify vent and drain connection locations, and maintain clearances required for insulation and maintenance access

- Commercial Plumbing: Mechanical contractors installing building service systems use measuring tools to maintain consistent pipe runs, verify proper slope for drainage systems, and ensure connections align with architectural features and other building systems in congested ceiling and wall spaces

- Shipbuilding: Marine pipefitters face unique challenges working with complex three-dimensional piping in confined spaces aboard vessels, depending on compact measuring tools that function in awkward positions while maintaining accuracy for systems critical to vessel safety and operation

- Food Processing: Sanitary piping systems require precise measurements to achieve proper drainage and cleaning capabilities, with fabricators using specialized tools to verify slope requirements, ensure smooth transitions without product trap areas, and maintain clearances needed for cleaning equipment access

Daily Pipe Measurement Tools Maintenance and Care

Regular cleaning extends tool life and maintains measurement accuracy throughout years of service. After each use, wipe tools clean of cutting fluids, metal shavings, welding spatter, and other contaminants that accumulate during pipe fabrication work. Pay special attention to sliding components, adjustment mechanisms, and measurement scales where buildup can affect tool function or obscure markings. Use appropriate cleaning solvents for stubborn residues, followed by light oil on moving parts to prevent corrosion in humid shop environments.

Proper storage protects measuring tools from damage and maintains calibration between uses. Store tools in dedicated toolboxes or wall-mounted racks rather than leaving them on work surfaces where they risk damage from dropped materials or moving equipment. Keep tools away from areas with high heat, excessive moisture, or corrosive chemical exposure that can degrade materials or affect accuracy. Consider using foam-lined cases for precision instruments like angle protractors or flange aligners that require protection during transport between job sites.

Periodic accuracy verification ensures tools continue providing reliable measurements throughout their service life. Compare tool readings against known standards or recently calibrated instruments, checking multiple points across the tool's measurement range. Tools showing inconsistent readings, damaged scales, or loose adjustment mechanisms need professional calibration or replacement. Most professional-grade pipe measuring tools maintain accuracy for many years with proper care, but tools subjected to drops, impacts, or extreme conditions may require more frequent verification.

How long do pipe measuring tools typically last? Basic wrap-around markers and simple measuring aids often provide 5-10 years of reliable service with normal care in typical shop environments. Precision instruments like angle protractors, flange aligners, and center-finding tools can last 10-20 years or more when properly maintained and protected from abuse. Tool longevity depends heavily on work environment, frequency of use, and handling practices. Investing in quality tools from reputable manufacturers and following proper care procedures maximizes tool life and maintains accuracy.

How do workers know when pipe measuring tools need replacement? Tools showing worn or illegible measurement scales, bent or damaged components, loose adjustment mechanisms, or inconsistent readings require replacement. Magnetic tools that no longer hold securely to pipe surfaces, wrap-around markers that don't maintain shape, or angle-finding tools that don't return to zero position reliably have reached end of service life. Rather than compromising work quality with worn tools, replace questionable instruments before they cause measurement errors that lead to rework or safety concerns.

Precision Measuring Equipment Safety Standards and Certifications

Pipe measuring tools themselves typically don't require specific safety certifications, but the work they support must meet relevant industry standards for piping systems. Accurate measurements help ensure completed pipe installations comply with ASME B31 piping codes, ANSI standards for dimensional tolerances, and industry-specific requirements for process piping, power piping, or building services. Proper measuring practices contribute to overall project compliance by reducing installation errors that could create safety hazards or system failures.

Quality measuring tools from reputable manufacturers meet dimensional accuracy standards appropriate for their intended applications. Professional-grade instruments typically provide accuracy within 1/16 inch or better, sufficient for most industrial piping applications. Precision instruments used for critical applications may offer accuracy to 1/32 inch or finer tolerances. Understanding required accuracy for your specific applications helps select appropriate tools without overpaying for unnecessary precision or risking quality issues from inadequate accuracy.

Workplace safety practices require workers using measuring tools to wear appropriate safety glasses and eye protection equipment along with protective gloves for hand safety when working around pipe fabrication operations. Even simple measuring tasks occur in environments with flying debris, sharp edges, and other hazards requiring proper personal protective equipment. Companies should include proper tool use in safety training programs, emphasizing correct handling techniques that prevent injuries from dropped tools, pinch points on adjustable components, or sharp edges on damaged instruments.

Best practices recommended by industry experts include establishing tool inspection procedures, maintaining calibration records for precision instruments, and replacing worn or damaged tools promptly. Professionals suggest keeping tool storage areas organized to prevent damage and make equipment readily available when needed. Regular training on proper measuring techniques helps workers understand tool capabilities and limitations, reducing measurement errors that compromise work quality. Creating a culture that values accuracy and proper tool maintenance supports consistent quality across all pipe fabrication and installation projects.

Pipe Measuring Tools Pricing: Budget vs Premium Options

Entry-level pipe measuring tools suitable for occasional use typically range from $30 to $100, offering basic functionality for straightforward measuring tasks. These budget-friendly options include simple wrap-around markers, basic angle indicators, and standard measuring devices adapted for pipe work. While less expensive tools provide adequate performance for light-duty applications or shops that work with pipe infrequently, they may lack durability features, precise tolerances, or versatility needed for professional fabrication environments where tools face daily use and demanding conditions.

Professional-grade measuring instruments designed for commercial and industrial applications typically cost between $150 and $600 depending on complexity and capabilities. Mid-range professional tools offer robust construction, accurate measurements across wide diameter ranges, and features like magnetic mounting or multiple marking positions that increase productivity. These tools provide reliable performance through years of regular use, making them appropriate for fabrication shops, construction contractors, and maintenance operations where accurate pipe work directly affects project success and profitability.

Specialized precision instruments for critical applications or unique measuring requirements can exceed $600, with comprehensive measurement systems or electronic instruments reaching several thousand dollars. These premium tools serve operations where extreme accuracy matters, such as power plant construction, aerospace applications, or pharmaceutical processing systems with stringent tolerance requirements. Advanced features may include digital readouts, data logging capabilities, or specialized functions for specific pipe materials or configurations. Companies working on high-value projects or critical systems often find that precision measuring tools prevent costly errors that far exceed tool investment.

Long-term value considerations extend beyond initial purchase price to include tool longevity, measurement accuracy, and productivity improvements. Quality measuring tools that last 10-15 years with proper care cost less per year of service than budget options requiring replacement every few years. Accurate measurements reduce material waste, minimize rework time, and help teams complete projects within estimated labor hours. Calculate total cost of ownership including replacement frequency, accuracy-related rework costs, and productivity differences when comparing tool options. Many businesses find that investing in professional-grade tools from manufacturers like Jackson Safety provides better value through improved reliability and performance.

Before Purchasing Pipe Measuring Equipment - Selection Checklist

- Verify tool covers your required pipe diameter range with adequate margin for occasional oversized projects

- Check magnetic mounting strength if working primarily with ferrous pipe materials in overhead or awkward positions

- Assess whether budget tools meet accuracy requirements or if investing in professional-grade instruments prevents costly errors

- Confirm compatibility between measuring tools and marking instruments currently used in your operation

- Evaluate how frequently tools will be used to determine appropriate durability level and construction quality

- Consider purchasing tool sets that include multiple complementary instruments for comprehensive measuring capabilities

- Establish proper storage locations and maintenance procedures before adding new tools to shop equipment inventory

- Review manufacturer warranty coverage and availability of replacement parts for tools requiring periodic component replacement

Investing in quality pipe measuring tools improves work accuracy, reduces project costs, and supports consistent fabrication quality across all piping projects. Whether you're equipping a new fabrication shop, upgrading worn equipment, or expanding capabilities for specialized applications, selecting appropriate measuring tools based on your specific requirements ensures you get maximum value from your investment. All Safety provides professional-grade pipe measuring tools designed for demanding industrial and commercial applications, helping businesses across North America maintain high standards for piping fabrication and installation work. Information current as of October 1, 2025.

- Product

- Qty in Cart

- Quantity

- Price

- Subtotal

-

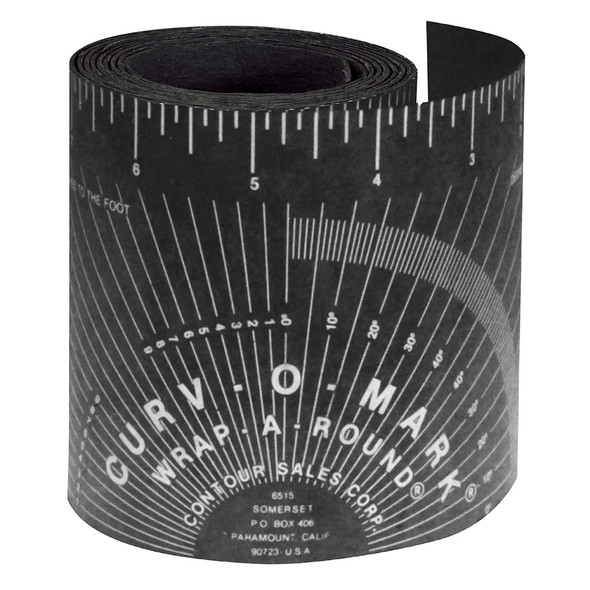

Wrap-A-Round | Jackson Safety

Jackson Safety

$32.98 - $90.61Description Jackson® Curve-O-Mark® Wrap-A-Round Tools are used by pipe fitters and welders alike this is an economical precision tool used to mark straight lines around pipes or to mark a straight edge prior to welding or cutting. Flexible...$32.98 - $90.61 -

#9 Curv-O-Mark Fitter Welding Protractor | Jackson Safety

Jackson Safety

$40.36Descrpition Centering heads aid in the settings of centerlines establishing angles and marks for butt-ins locating points inside pipes and tanks laying out keyways and measuring declivity. Features a 4″ Y-type head fitted with an adjustable dial...$40.36 -

Curv-O-Mark Radius Marker | Jackson Safety

Jackson Safety

$62.32 - $148.55Description Jackson® Safety Curve-O-Mark® Radius Markers are used by pipe fitters and welders alike for an economical precision tool used to mark straight lines around pipes or to mark a straight edge prior to welding or cutting. Made with an...$62.32 - $148.55 -

Curv-O-Mark Dial Set Level (DSL) | Jackson Safety

Jackson Safety

$77.76Descrpition The Jackson® Safety Curve-O-Mark® Dial-Set Level is an adjustable bubble protractor used with a number of popular Jackson Safety Curv-O-Mark tools. Bubble is cast in the aluminum dial for durability Reads in 2.5-degree...$77.76 -

#2 Curv-O-Mark Marker Adapter | Jackson Safety

Jackson Safety

$92.83Description Jackson® Safety Curve-O-Mark® Pipe Marking Tools are used by pipe fitters and welders alike for an economical precision tool used to mark straight lines around pipes or to mark a straight edge prior to welding or cutting. Includes...$92.83 -

#19 Curv-O-Mark Multi Trammel Heads | Jackson Safety

Jackson Safety

$103.84Description Jackson® Safety Curve-O-Mark® Pipe Marking Trammels are used to conveniently measure distance between two points that are too long to be reached with dividers. Heads feature radius set points cast in alignment with marking pointer...$103.84 -

#8 Curv-O-Mark Pro-Mag Level | Jackson Safety

Jackson Safety

$168.70Description Jackson® Curve-O-Mark® offers a full range of leveling tools and flange aligners designed specifically for professional pipe-fitters steel workers and electricians. Material: Made of durable lightweight cast aluminum material; This...$168.70 -

#6 Curv-O-Mark Center Head | Jackson Safety

Jackson Safety

$186.53Description Centering heads aid in the settings of centerlines establishing angles and marks for butt-ins locating points inside pipes and tanks laying out keyways and measuring declivity. Features a 4″ Y-type head fitted with an adjustable dial...$186.53 -

#5 Jumbo Curv-O-Mark Marker Adapter | Jackson Safety

Jackson Safety

$187.31Description Jackson® Safety Curve-O-Mark® Pipe Marking Tools are used by pipe fitters and welders alike for an economical precision tool used to mark straight lines around pipes or to mark a straight edge prior to welding or cutting. Includes...$187.31 -

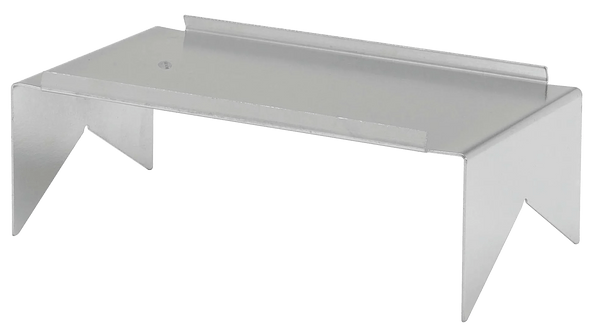

#20 Curv-O-Mark Dual Angle Flange Level - Non-Magnetic | Jackson Safety

Jackson Safety

$222.97Description Jackson® Curve-O-Mark® offers a full range of leveling tools and flange aligners designed specifically for professional pipe-fitters steel workers and electricians. Material: Made of durable lightweight cast aluminum material; This...$222.97 -

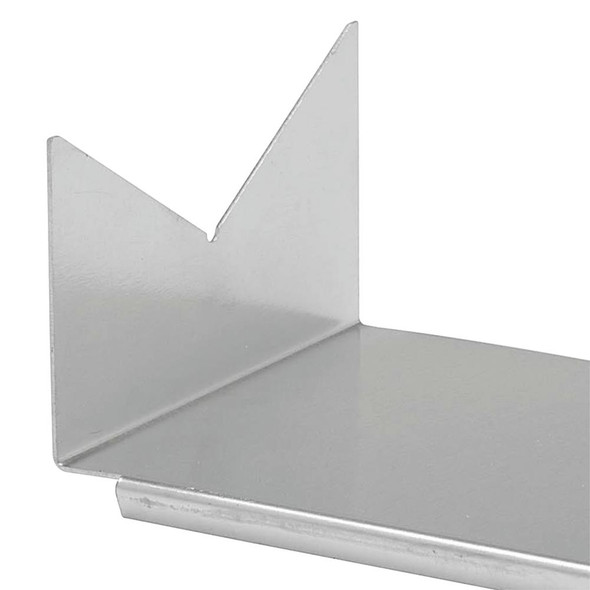

#10 Curv-O-Mark Pipe Flange Aligner | Jackson Safety

Jackson Safety

$246.64Description Jackson® Curve-O-Mark® offers a full range of leveling tools and flange aligners designed specifically for professional pipe-fitters steel workers and electricians. Material: Made of durable lightweight cast aluminum material; This...$246.64 -

#32 Curv-O-Mark Flange Aligner Base | Jackson Safety

Jackson Safety

$257.56Descrpition Jackson® Curve-O-Mark® offers a full range of leveling tools and flange aligners designed specifically for professional pipe-fitters steel workers and electricians. Material: Made of durable lightweight cast aluminum material; This...$257.56 -

#33 Curv-O-Mark Universal Base | Jackson Safety

Jackson Safety

$278.60Descrpition Jackson® Curve-O-Mark® offers a full range of leveling tools and flange aligners designed specifically for professional pipe-fitters steel workers and electricians. Material: Made of durable lightweight cast aluminum material; This...$278.60 -

#7 Curv-O-Mark Jumbo Centering Head | Jackson Safety

Jackson Safety

$289.35Description Centering heads aid in the settings of centerlines establishing angles and marks for butt-ins locating points inside pipes and tanks laying out keyways and measuring declivity. Features a 4″ Y-type head fitted with an adjustable dial...$289.35 -

#1 Curv-O-Mark Marker | Jackson Safety

Jackson Safety

$347.31Description Jackson® Safety Curve-O-Mark® Pipe Marking Tools are used by pipe fitters and welders alike for an economical precision tool used to mark straight lines around pipes or to mark a straight edge prior to welding or cutting. Includes...$347.31 -

Curv-O-Mark Worker Kit | Jackson Safety

Jackson Safety

$627.98Descrpition Jackson® Safety Pipe Fitting & Welding Marking Kits come in a secure metal carrying case to transport your tools of the trade easily and conveniently. A great value for your pipe fitting and marking needs this kit comes in a...$627.98